What do you know about the types of polystyrene grades? Three different grades are made of polystyrene: General Purpose polystyrene, High Impact Polystyrene (HIPS), and expanded grade. Due to the high fragility of polystyrenes, these materials are polymerized with polybutadiene. This process causes To increase the strength of polystyrenes, this type of polystyrene is called Impact, improved with rubber, and the percentage of polystyrene in these products usually varies between 88% and 97%.

Introduction of polystyrene grades

The production process of polystyrene grades

There are various methods for producing different types of polystyrene grades. Emulsion, suspension, bulk, and solution methods can be used to produce these products. In solution methods, the monomers are dissolved in a solution such as ethylene benzene and then the polymerization process is performed.

In suspension methods, monomers in water are used as suspensions. Solution and bulk methods are known as homogeneous methods and emulsion and suspension are introduced as heterogeneous methods.

One of the most common methods currently used to produce polystyrene grades is the bulk method, which we will explain below.

Production of polystyrene grades by the bulk method

This operation can be formed in two common ways the form of batch or continuous. In the following, we will describe the batch process.

Polystyrene grades can be made by various batch processes. The batch operation generally has a high conversion efficiency and only a small amount of reacting styrene will leave the reactor and return to the reactor. To produce High Impact Polystyrene grade, polybutadiene rubber solvent must be added to the feed solvent, which dissolves in hot styrene.

Most grades, such as GPPS and expanded, each have their production method. For example, in expanded grades, a material is added to the polymer that increases its volume.

General Purpose polystyrene grade

As we said at the beginning, polystyrene is produced in 3 grades. GPPS or General Purpose polystyrene is known as a thermoplastic polymer. This material was first produced by the German company “Industries I.G.Farben”. This product was used as insulation in the electronics industry.

Currently, this type of polystyrene grade is considered one of the most popular plastics that is used in most industries. One of the reasons for using this type of polymer is its high ductility, transparency, and low price. The most common uses of the General Purpose grade are in disposable tableware, sports equipment, toys, electrical appliances, watch cases, radios, and televisions.

Expanded polystyrene grade:

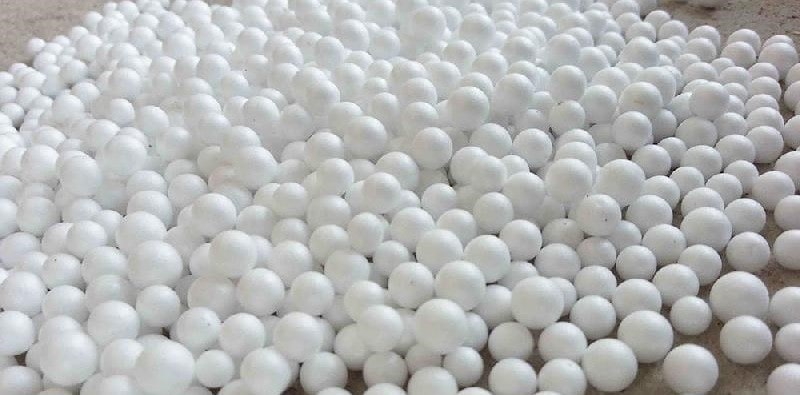

One of the most widely used examples of grade polystyrene is the expanded type, which is made from a combination of dehydrogenated gasoline crown and polystyrene monomer. This type of polystyrene has a linear chain and belongs to the family of thermoplastics. Expanded polystyrene grades are often known by particle size, particle size. There are other grades in the category of expanded polystyrene, known as antistatic and slow-burning.

Expanded polystyrene grade has more than 50 years, which has a special place in the packaging industry. This material is used for packaging products that require precise packaging.

Extruded polystyrene grade:

Melted polystyrene beads are continuously injected into extruded molds under pressure. During the extrusion operation, expanding gas is injected into the molten polystyrenes. During this process, polystyrene foam becomes homogeneous and cellular. One of the most common gases used in the injection process is CO2 expansion gases.

Production of polystyrene grade by bulk method

Applications of various grades of polystyrene

Polystyrene is used in the packaging of foods such as meat and vegetables, PS films, and other packaging that requires transparency.

Injected grades used in melted form are widely used in the production of cosmetic containers, jewelry boxes, packaging for photographic and film equipment.

Other applications of polystyrene grades are used to make refrigerator door strips, vases, utensils, and smoke detectors. Today, the use of polystyrene grades is used in all industries due to their lightweight and reasonable price.