Types of polystyrene containers

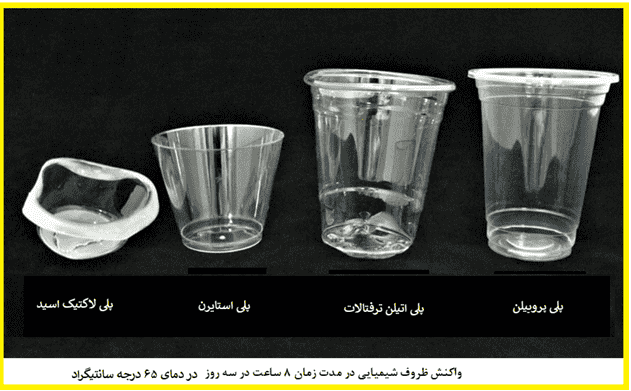

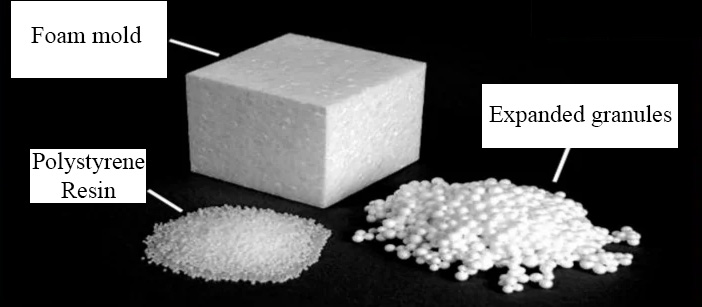

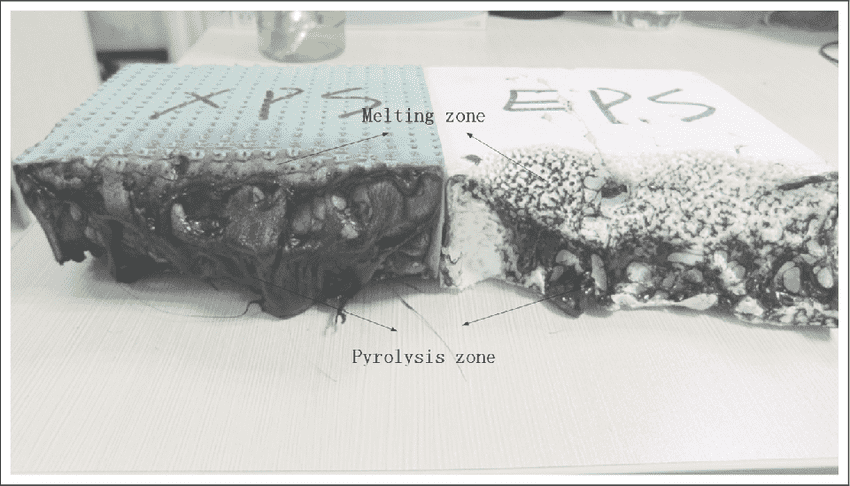

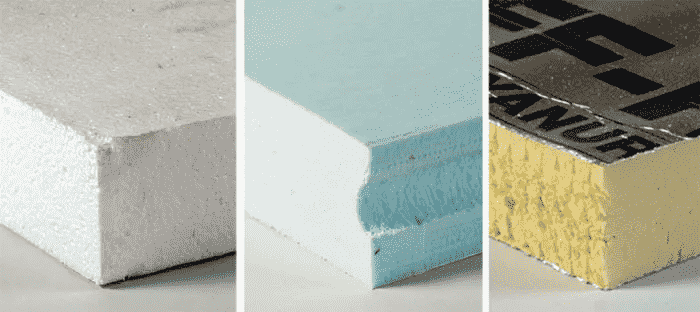

Polystyrene containers are divided into two groups, EPS and XPS polystyrene. With these containers, all kinds of food and drinks can be packed. Food temperature conditions are maintained in these containers. Polystyrene containers are produced in two types of matte and transparent and foam. Since toxic chemical raw materials are used in the production of these dishes, it can be concluded that eating food in these dishes is not correct. It is recommended to take the food out of them and heat it in the dishes on the stove or microwave.

Resistance of polystyrene containers

The strength of polystyrene containers is good for preserving food inside the containers. You can stack several containers of food together.

Colored matte polystyrene containers

Polystyrene containers are used to transport caught fish

These polystyrene containers are suitable for carrying marine fish, crops, and other marine life. Live marine prey can be easily packaged and transported with these containers.

Polystyrene food containers

These containers are used to carry a variety of foods. Food distribution companies and supermarkets use these containers.

These containers are perfect for carrying all kinds of food, vegetables, fish, meat, and fruits. Egg packaging, outdoor foods, disposable cups of tea and coffee, all types of food packaging are in this group. Bottles of water and non-alcoholic carbonated beverages can be included in this group.

From there, chemicals were used to make these dishes; Therefore, be careful not to put hot food in these containers, because the heat of the food releases toxic chemical molecules and eventually penetrates the food.

Matte white dishes

Polyethylene terephthalate or PET

This chemical is used in the design and production of beverage bottles and food sauces.

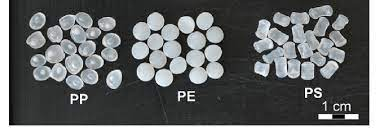

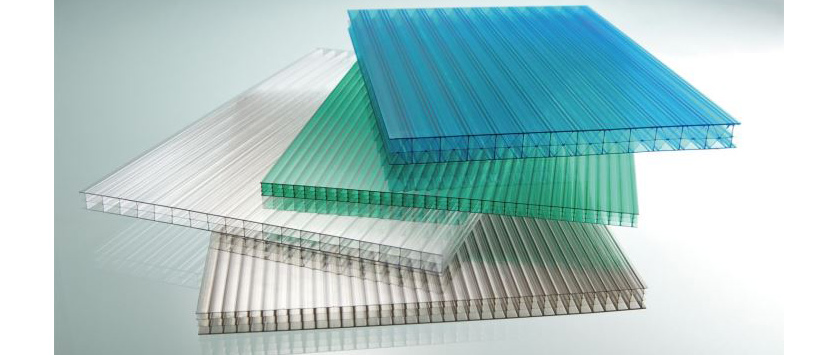

Polyethylene or PE food containers

These packaging containers are transparent and brittle and are used for packaging vinegar, dairy, and oil.

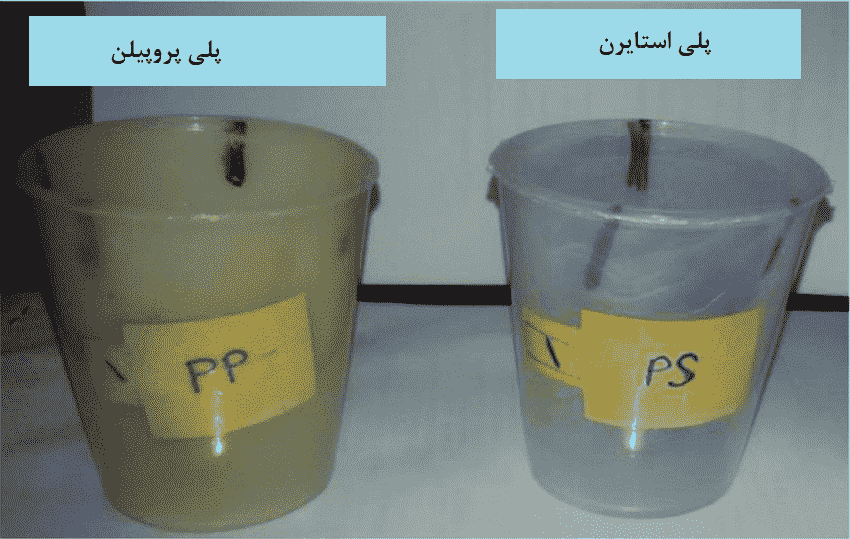

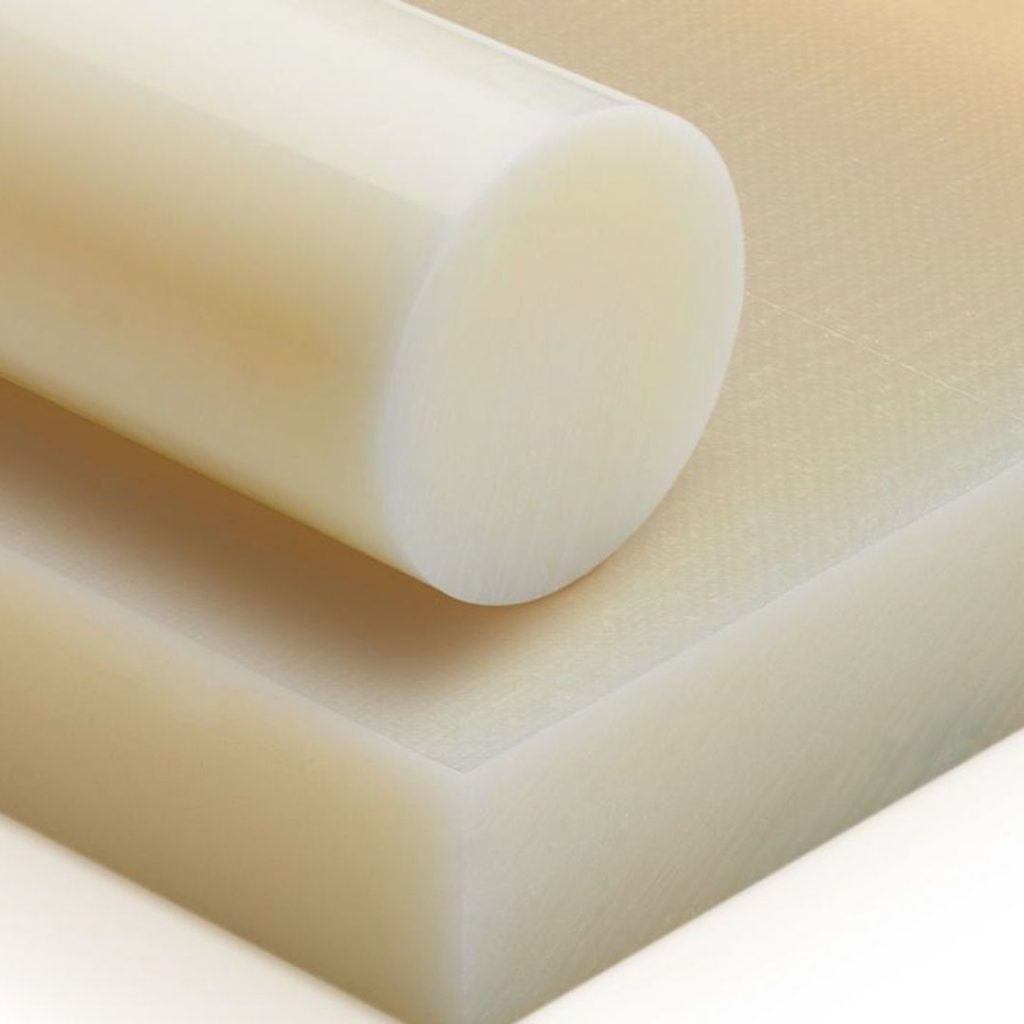

Polypropylene or PP containers

The color of the packaging of these materials is matte and semi-transparent. In addition, these containers are strong and do not crumble and do not break. These containers do not contain toxic substances. For this reason, food is healthy and this substance is used to make yogurt dishes and sauces.

Polyvinyl chloride or PVC containers

These containers are made of plastic and are used for food packaging. This type of plastic material is made in different conditions than others.

Disposable aluminum containers

It is considered the healthiest container for food packaging. Food stays in these containers for a long time. It is beautiful, compact, and beautiful and is resistant to heat, and does not change shape. They can be used in ovens and microwaves. They do not pollute the environment. These dishes are used in hotels, restaurants, and industrial kitchens. Compared to others, aluminum containers pollute the environment less but their price is higher than others.

Polystyrene containers for foods

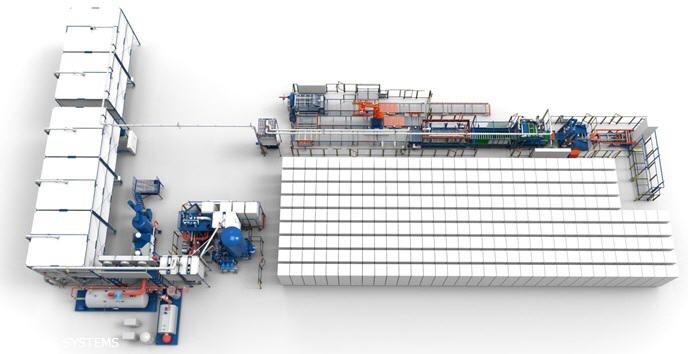

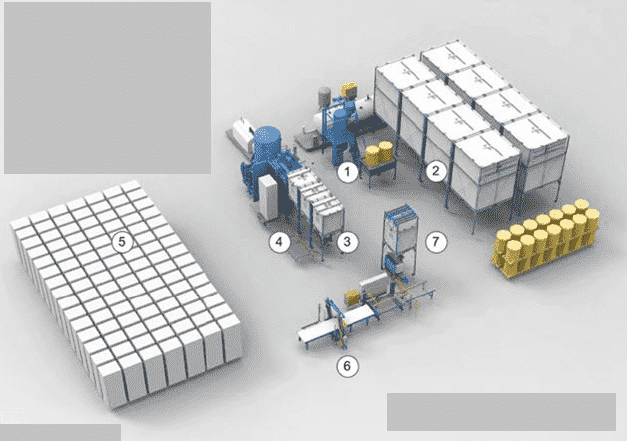

Polymer plastic containers

Polymer is a combination of several chemicals; With this material, different types of plastic containers can be produced. The raw material is toxic and factories producing these materials need to have a license to produce these products. These containers are made by combining several chemicals.

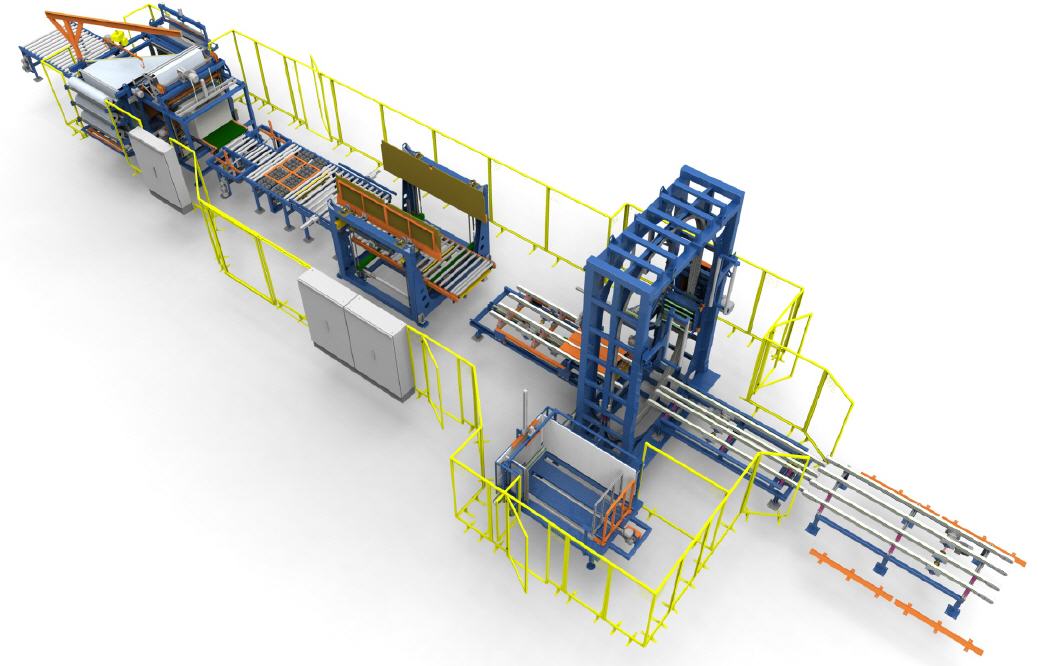

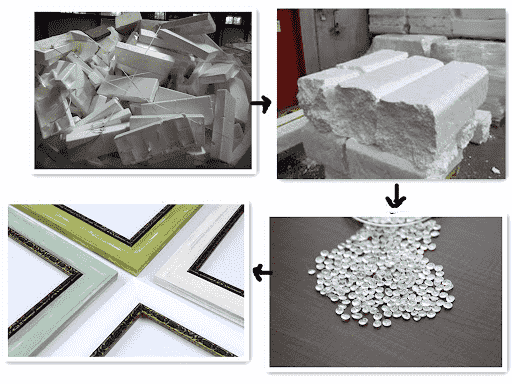

Disposable foam containers

Foam utensils are another type of polystyrene utensils. The gas enters the polystyrene grains and these containers are formed. These containers are suitable for packing wet and hot food up to a temperature above 65 ° C. They are much better than paper containers. Foods with a temperature above 160 degrees should be noted that hexane gas is released and eventually this gas enters the body and causes headaches.

High impact polystyrene (HIPS) and general purpose polystyrene (GPPS) are also used in the manufacture of food packaging containers.

Disposable paper containers

These dishes are very low consumption compared to others and are mostly used in service places. Food temperature remains the same in disposable paper containers; In addition, these containers can be easily recycled. Stylish is another feature of them. In addition, they are produced with less energy than others.

These dishes can not be used in the dairy industry, and this is due to the infiltration of water into the paper, and it is clear! It is the best alternative for plastic containers. Since they are healthier than plastic containers, their price will be higher.

Conclusion

Polystyrene containers are produced in two types of matte and transparent, and foam. Since toxic chemical raw materials are used in the production of these dishes, it can be concluded that eating food in these dishes is not correct. It is recommended to take the food out of them and heat it in the dishes on the stove or microwave. The heat releases toxic chemical molecules into polystyrene packaging containers.

Even the impact of metal spoons and forks on the inner layer of utensils releases dangerous chemical raw materials that are harmful to the human body.