Table of Contents

Polystyrenes and PS-based plastics are widely used due to their low cost, ease of processing, and wide range of grades. General Purpose polystyrene or GPPS, is produced by the polymerization of styrene monomer in the form of a transparent cylindrical granule. Then, GPPS is converted into a final product by injection molding or extrusion at 190-230 ° C. This chemical material has good clarity and strength and is used in clear or colored form to make the final product shiny and inexpensive.

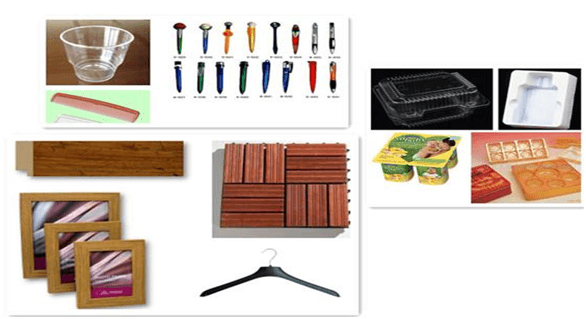

General Purpose polystyrene uses

Various applications of General Purpose polystyrene (GPPS) in the world

General purpose polystyrene, abbreviated as “GPPS”, is made from the styrene monomer polymer through a suspension process. It is a solid product that is compressed into granules to produce a wide range of products. This material has high clarity and transparency. Iran General purpose polystyrene (GPPS) is relatively strong and resistant to ambient pressure.

This material flows easily, which makes it suitable for use in finished product molds such as toys, CD caps, hangers, and plastic cups. This polystyrene is used in items such as IT equipment, jewelry boxes, and other types of containers. Iran GPPS is also used to make disposable medical products such as laboratory tubes, laboratory kits, Petri dishes, bath accessories, and gardening equipment. So it can be used in different cases.

Uses of General Purpose polystyrene

Other types of polystyrene

- High-density polyethylene:

High-density polyethylene is used in the manufacture of household appliances such as utensils, lids, and bags, as well as for injection molding, impact, and rotational molding. This material is strong, easy to process, and has high transparency. - High Impact PolyStyrene(HIPS):

Unlike General Purpose polystyrene (GPPS), High Impact PolyStyrene (or HIPS) contains rubber and is used in the manufacture of products that must be impact resistant and less transparent than GPPS. It has a standard flow, is transparent but less than GPPS, is crack resistant, and is used in injection molding. These applications include sheets for freezers. - Polypropylene:

Polypropylene is used for many applications. It can also be injected. This material is used for products such as containers and toys. This feature is characterized by its strength, processing properties, and transparency.

Polypropylenes

- Ethylene-vinyl acetate:

This material is used in molding processes and thermal adhesives. - Low-density linear polyethylene:

This material can be mixed with other resins. Uses range from ice cans to lids, disposable tableware, auto parts, and toys. This material can withstand low temperatures well and has high transparency. - Copolymer:

The copolymer is used to make transparent doors and enclosures. It is strong and clear. This material is commonly used in the manufacture of hard consumer goods.

Copolymers

As mentioned above, Iran General purpose polystyrene and its various types are used for a wide variety of applications. Cost-effectiveness of production, ease of storage, and molding properties of materials have made the recycling of such products even more important. Without polystyrene, many disposable products and appliances would not be available today.

What are the differences and similarities between HIPS and GPPS?

gpps vs hips

Polystyrene (PS) is one of the most popular thermoplastic materials in the world, but depending on their application, you may want to use High Impact PolyStyrene (HIPS) or General Purpose Polystyrene (GPPS). Each of them has unique features that you should research well before deciding on the best option for the project and the end-use.

At MohebBaspar (Best Iran General purpose polystyrene company), we are proud to provide our customers with specialized product properties in the field of product development. Read more about the type of polystyrene you want to choose as your final product.

The differences between GPPS and HIPS:

- While both GPPS and HIPS are considered low-cost, General Purpose Polystyrene is more cost-effective.

- GPPS is brittle and has lower impact resistance as well as less dimensional stability than HIPS.

- Unlike HIPS, GPPS has a thin transparent edge. GPPS has a glass-like resolution that has made it popular in food packaging, this can be easily molded and shaped into various shapes.

What do HIPS and GPPS have in common?

While there are some key differences between HIPS resins and GPPS. But they have several things in common:

- Both resins are inexpensive, hard, and rigid.

- They are easy to process and produce.

- Processing methods include injection molding, extrusion, pneumatics, and thermoforming.

- Both are FDA compliant, which is why they are widely used in kitchen utensils and food packaging.

- Both are used in health applications and are recyclable.

What are the unique features of General Purpose Polystyrene (GPPS)?

features of GPPS

- General Purpose polystyrene production is simply easy! In other words, GPPS can be polymerized by a variety of synthetic methods.

- GPPS is soluble in aromatic hydrocarbons, chlorinated hydrocarbons, aliphatic ketones, and esters. It can be resistant to the function of some mineral oils, organic acids, alkalis, and salts.

- It has low water absorption.

- GPPS can maintain its mechanical properties and dimensional stability even in wet conditions.

- It has excellent electrical properties.

- Resistant to environmental conditions is not affected by changes in temperature and humidity and is not affected by canopy depletion.

- X-ray resistant, odorless and tasteless.

- It is non-toxic.

- The main disadvantage of General Purpose polystyrene is its fragility as well as lack of resistance to impact and heat, and it can be used only at low temperatures and low loads.

Manufacturers of recycled plastics

Plastic recycling is now recognized as a leading brand. Many countries around the world are working on projects to create different types of reusable plastics. The established name in this field is abbreviated (GRM POLYMER). These companies supports new inventions and startups by producing cheaper raw materials.

They recycle plastic waste and turn it into reusable General purpose polystyrene (GPPS) plastic pellets. These pellets are useful for producers of new products and their production cost is not very high.

plastic recycling

Thermoplastic molding methods

Thermoplastic molding methods

In the evolving world, plastic is used to make everything from car body parts to artificial human body parts. To create vital components and ensure optimal performance, many manufacturers choose to use plastic injection molding.

Depending on the diverse needs of the industry, there are different methods of plastic molding, each of which offers unique features and benefits. Below are some of the most common different methods of plastic molding.

Pneumatic molding to produce General Purpose Polystyrene

The method of blow molding is similar to the blowing steps in the glass. To blow a one-piece mold, a large piece of plastic, usually in the shape of a tube, is heated and inflated with air and continues until the entire mold is full. In this way, General Purpose polystyrene (GPPS) becomes the desired shape.

After cooling, the newly formed plastic part is removed from the mold. Pneumatic molding is especially useful for producing one-piece, large-volume hollow objects, as this process can quickly create a uniform, thin-walled containers.

Suitable for small objects such as bottles, as well as larger containers such as storage containers and drums. Materials used in this method include low-density polyethylene, high-density polyethylene, polyethylene terephthalate, polypropylene, and polyvinyl chloride.

Pneumatic molding

Compression molding

Pressure molding involves placing heated General Purpose polystyrene inside the heated mold, then closing it to compress the plastic to the desired shape. After cooling, the plastic piece comes out of the mold. The heating process assures you that the final product will maintain its integrity and shape.

General Purpose polystyrene manufacturing

Compression molding has many unique benefits. It is both affordable and highly efficient. This process is also quite diverse and allows manufacturers to create parts that vary greatly in thickness, length, and complexity.

Because high-pressure composites are often used in advanced composites for plastics, the manufacturing process makes the parts more durable and popular, making them popular in a wide range of industries.

For example, this method typically uses high-strength materials such as thermal resins, fiberglass, and reinforced plastics, resulting in products that are more resistant to other molding processes. This method is used to produce parts in a wide range of applications, including auto parts, home appliances, and wooden hangers.

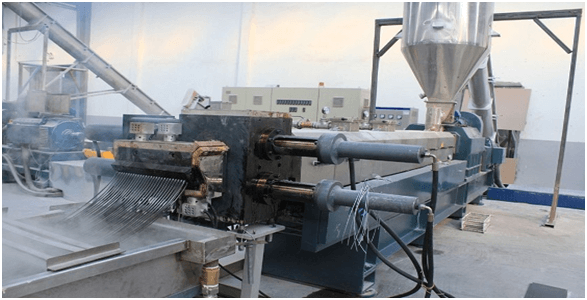

Extrusion molding

While extrusion is used in a variety of plastic molding methods to place GPPS resins in the mold, extrusion molding molds molten plastic directly into the mold. This process is unique in that the shape of the mold determines the shape of the final product. The extrusion mold is ideal for making parts with long lengths and uniform cross-sections.

Similar to plastic injection molding, the extrusion molding machine has a screw that rotates into the feeder to feed General purpose polystyrene (GPPS) plastic resin. The molten plastic then moves through the mold, creating a long tubular shape. The cooled extrusion then leaves the machine. Extrusion mold is suitable for hollow parts such as pipes and straws.

Extrusion molding

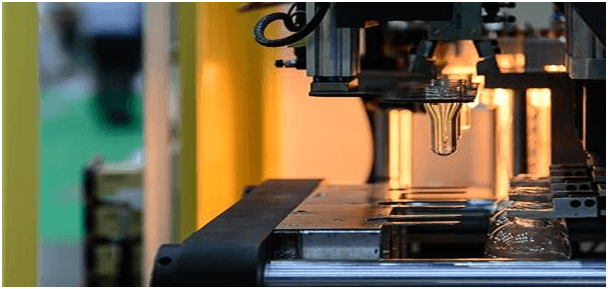

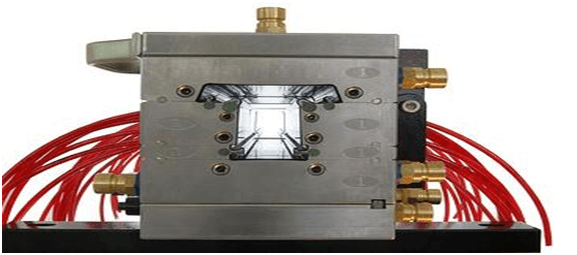

Injection molding

Among the various molding processes available, injection molding is the most diverse, as it can be used to create a variety of parts both in size and shape. The basics of injection molding are quite simple, but the actual process can be very complicated when it comes to maintaining component compatibility. This process involves injecting molten plastic into a mold made of steel.

The mold itself has cavities that make up the parts. After injection, the molten plastic fills the cavities and the rest of the mold. After cooling, the parts are removed by pins.

Thanks to the excellent flexibility, the injection mold can be used to create everything from large car parts to small and complex parts and in surgical equipment. Injection molding also allows for high customization, as plastic resins and various additives can be used.

GPPS in custom products

Injection molding is best suited for creating very large volumes of precision parts. Once production begins, the cost of each part is significantly reduced, and this process is very economical for high-volume production.

General Purpose polystyrene Plastic injection molding is a very reliable solution for producing a large number of precise and compatible components. It is also more efficient and cost-effective than other molding methods because it produces much less waste. As a result, injection molds are often used to make high-quality parts in high volume.

Conclusion

Plastic is one of the most popular and useful materials in modern times. We now use about 20 times more plastic than we did 50 years ago. We can optimize the life of plastics by reusing and recycling materials as much as possible. Certainly, plastic recycling is a good step in controlling the accumulation of pollutants in the soil.

Moheb Baspar Idea Gostar Company is engaged in the GPPS production and sale for domestic consumption and export of various types of polystyrene like General Purpose polystyrene. To know the price of General Purpose polystyrene (GPPS), get advice, and buy General Purpose polystyrene in your desired grades, you can contact our experts in the business unit.