Table of Contents

High Impact PolyStyrene (HIPS), as one of the most practical thermoplastics in the world, has various applications. Here, we are proud to offer you a wide range of applications as a specialist supplier of High Impact Polystyrene (HIPS) Sheets, with the necessary materials and equipment.

High Impact PolyStyrene (HIPS) is a modified form of polystyrene.

Polystyrene is an adaptable plastic used to produce a wide range of consumer products. As a hard and solid plastic, it is often used in products that require order, such as food packaging and laboratory materials.

High Impact PolyStyrene sheets

When combined with various colored materials, additives, or other plastics, polystyrene is used to make home appliances, electronics, auto parts, toys, garden pots and equipment. Polystyrene plastic is a thermoplastic material that is naturally transparent and available in different grades:

General Purpose Polystyrene (GPPS):

GPPS has a general application, called crystalline polystyrene. GPPS is a transparent and brittle product resulting in the polymerization of styrene monomer.

gpps vs hips manufacturing

High Impact Polystyrene (HIPPS):

High Impact PolyStyrene (HIPS) is a type of high-strength polystyrene, commonly known as “HIPS”. This is a modified name of General Purpose polystyrene. The addition of rubber results in a product with lower transparency instead of much higher strength and durability than the previous combination.

High Impact Polystyrene schema

Expanded Polystyrene(EPS) or Extruded Polystyrene(XPS):

EPS is a foamed version of polystyrene, often referred to as “Ionolite”, the name for EPS, which was chosen as a trademark in 1941 by DowChemical. It is scalable and has been considered in terms of insulation properties and infrastructure.

Polystyrene Foam:

Polystyrene Foam can be more than 95% in our environment. It is widely used for making home and appliance insulation, protective packaging, corrugated boards, food service, and packaging of food and car parts.

Manufacturing High impact Polystyrene foam

Some facts about Iran High Impact PolyStyrene

Choosing the right polystyrene for your use can be a bit confusing, especially if you are new to the industry. HIPS is a very versatile, economical, and durable material that shows good impact resistance and like all thermoplastics, the material can become soft and flexible when heated and solidified again after cooling. In general, Iran High Impact PolyStyrene (HIPS) works very well with thermoforming processes.

High Impact PolyStyrene producing

These factors alone (HIPS) make it an excellent material for component production. Here are some important facts about High Impact Polystyrene (hips):

High Impact PolyStyrene (HIPS) is an impact resistant material

As the name implies, Iran High Impact PolyStyrene is a type of polystyrene that has higher impact resistance. Polystyrene homopolymer can often be brittle and, when combined with other materials, can become more impact resistant. This form of polystyrene is typically produced by adding about 5 to 10 percent rubber copolymer or butadiene.

This material increases the hardness and strength of the polymer and leads to the production of a very rigid product suitable for packaging applications. Due to the durable nature of this material, HIPS sheets with rigid plastics are used in a wide range of food, medical, consumer goods, cosmetics, industrial and horticultural packaging.

High Impact Polystyrene at food packing

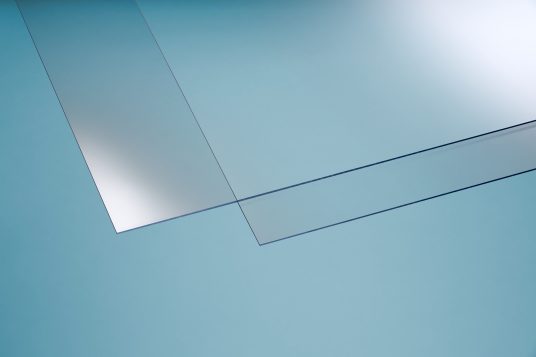

High Impact PolyStyrene (HIPS) is an amorphous (transparent) polymer

Transparent High impact Polystyrene

Polymers show two morphological states in solid-state, amorphous (transparent) and semi-crystalline. While a semi-crystalline polymer refers to a polymer with organized and perfectly interconnected molecular chains, polymer chains are unorganized for amorphous (transparent) plastics.

In an amorphous (transparent) polymer, the molecules are randomly and interconnected. Polymer chains for amorphous materials are often compared to a plate of baked pasta to give you a clear picture of its organization or absence.

Amorphous (transparent) polymers, such as polystyrene, are resistant to the impact of isotropic currents, meaning that they shrink uniformly in the direction of flow and flow transversely. This usually causes less shrinkage and warping than semi-crystalline polymers. Amorphous polymers are usually transparent, however, High Impact Polystyrene (HIPS) is semi-transparent in its natural state.

HIPS is compatible with food packaging applications

Iran High Impact Polystyrene (HIPS) is certified by the US Food and Drug Administration (FDA) and is compatible with food packaging applications. The natural firmness of this material makes it nice for food packaging applications such as meat, cookies, bread, and vegetables.

While the moisture vapor transfer rate is not as good as other polymers, HIPS have moisture-insulating properties that make them suitable for short-lived products.

In addition, improved forms of High Impact PolyStyrene (HIPS) lead to the strength of the cracked polymer against environmental pressures, making it suitable for packaging fatty foods such as butter. It can also be used in low heat food packaging applications but is not recommended for cases where the packaging is heated above 185 degrees Fahrenheit.

Food packaging using HIPS

HIPS are good printable layers (sublayers)

HIPS can be made more beautiful by using a variety of printing methods, including screen printing, offset lithography, and flexography. It is compatible with crown treatment processes (polymer dryness), which helps reduce adhesion problems to plastics. In other hand, Buying High Impact PolyStyrene can improve your growth in the industry.

High Impact PolyStyrene (HIPS) is a recyclable material

For a world that needs to reduce its plastic waste, using a 100% recyclable plastic packaging solution, such as HIPS, is not a problem, especially for organizations that want to reduce their carbon footprint. Because High Impact Polystyrene is a thermoplastic that can be easily formed using heat, it can be recycled in a wide variety of applications.

Not only does this show how flexible the material is, but it can be useful beyond its original purpose. However, High Impact PolyStyrene (HIPS) and other recyclable forms of polystyrene are often not acceptable in recycling plants. In the UK, for example, only 30% of the UK population has access to factories that allow the recycling of HIPS products such as glasses and disposable tableware.

Unfortunately, this is part of a global problem where only 14% of the world’s plastic packaging is recycled annually. Because most recycling plants cannot sort and reprocess up to 50 different types of plastics. This wide variety means that plastic recycling is a complex task, especially when compared to how other materials are recycled.

High Impact Polystyrene recycling

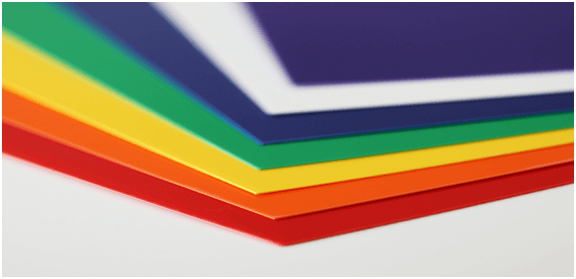

High Impact PolyStyrene (HIPS) can be easily customized

High Impact Polystyrene is a durable plastic that is easy to customize and is available in almost any color under the sun. It is compatible with a variety of processes and is therefore available in a wide range of additive colors, finishes, and packaging formulas.

Due to its amorphous (transparent) properties, High Impact PolyStyrene (HIPS) is paintable and suitable for design purposes. Moheb Baspar Company as a High impact polystyrene manufacturer is one of the best providers for you.

Product customization in different colors

High Impact polystyrene thermoforming

Once heated, HIPS is highly malleable, meaning that High Impact PolyStyrene thermoforming is a great way to produce the plastics customers need. To do this, large HIPS sheets are heated and placed on a custom tool. Then, to achieve the ideal shape and design, we use one of three methods to complete the thermoforming process.

1. Vacuum forming

Vacuum forming is used for large pieces of plastic that do not require much detail or sharp corners or edges. Although the most basic method is thermoforming, it is fast and cost-effective.

As soon as the plastic is heated and installed on the mold, a powerful vacuum is created between the mold and the plastic sheet, which sucks all the air between the sheet and the mold, and pulls the thermoplastic firmly towards the mold, creating a precise shape. Vacuum forming is often used to produce refrigerator liners and boat hulls.

Vacuum forming to produce High Impact Polystyrene

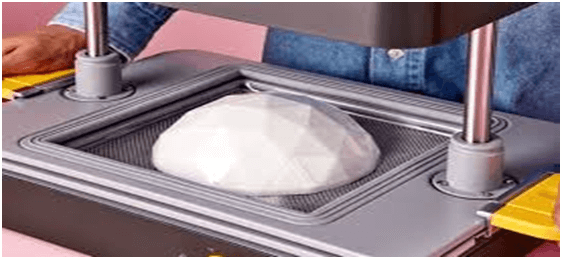

2. Pressure forming

When marked edges, corners, and details are necessary, we use pressure forming. Like vacuum forming, we place heated HIPS on the mold but then use high-pressure air to force the plastic. This force is three times the vacuum-forming force and creates a high level of detail.

Pressure forming is very precise and is often used in the manufacture of auto parts, including machine tool plates and electronic equipment.

Pressure forming to produce hips

3. Twin sheet forming

Twin sheet forming is the most sophisticated High Impact PolyStyrene (HIPS) thermoforming method. We heat two HIPS sheets at the same time, then place and fasten them. Make sure the two pieces are fully compressed. This method is used to create double-walled industrial products. Gas bottles and air ducts can also be made using twin sheet forming.

Properties of High Impact Polystyrene (HIPS)

High Impact Polystyrene has various properties that allow a wide range of applications for thermoplastics. High Impact Polystyrene (HIPS), due to its visual appearance like color options, transparency, texture, and ease of use, is one of the most widely used and popular plastics in the world.

Properties of High Impact Polystyrene

HIPS is a versatile, cost-effective, impact-resistant material that is easily used in manufacturing processes, such as vacuum forming. It bends and forms easily while maintaining durability. Its properties do not weaken after re-molding and it is very reliable.

It has a high degree of flexibility and can be molded over and over again to make it environmentally friendly because as mentioned above, HIPS is 100% recyclable. Due to the large number of properties that thermoplastics can offer, the use of High Impact PolyStyrene (HIPS) is very diverse. The rubber content gives HIPS more durability and impact resistance.

This thermoplastic, with its high strength and durability, is great for marketing purposes. It can also be used in the construction of heating chambers, replicas, and plastic toys. In addition, thermoplastics are commonly used to make cabinets and shower enclosures.

Advice and support from leading thermoplastics specialists

When choosing the right thermoplastic, it is important to compare the properties of each material with your needs. We know that some of our customers may not know much about thermoplastics.

But we do not prevent them from investing in the product. We have very deep knowledge and understanding of thermoplastics like HIPS. If needed, we can provide you with expert advice.

A Summary of introducing High Impact PolyStyrene manufacturing at MohebBaspar

Iran High Impact Polystyrene or HIPS sheets

Here, we can offer High Impact Polystyrene sheets in a wide range of sizes and thicknesses, so you can easily find the sheet you need here. If you are looking to buy high impact polystyrene (hips) in a certain size, you can also use our custom services. We can make custom size of the thermoplastic sheet for you and you can be sure that the price of durable polystyrene (hips) is reasonable.

Moheb Baspar Idea Gostar Company is active in the field of production and sale of High Impact Polystyrene (hips) for domestic consumption and export of various types of polystyrene, including the export of High Impact Polystyrene (HIPS). To know the price of High Impact Polystyrene, get advice, and buy High Impact Polystyrene (hips) in your desired grades, you can contact our experts in the business unit.