Table of Contents

Phthalic anhydride (abbreviated “PA”) is a white organic compound that has a distinct pungent odor. It is soluble in water, alcohol, and other organic solvents and is used in the manufacture of phthaleins and other dyes, resins, emollients, and insecticides. Phthalic Anhydride or PA is phthalic acid anhydride and plays an important role in the manufacture and production of plastic softeners.

It is currently obtained by the catalytic oxidation of o-Xylene or naphthalene. Iran Phthalic anhydride can also be obtained from phthalic acid. Iran Phthalic anhydride acts as an intermediate in organic chemistry because it is dual-functional and readily available. As a primary use of phthalic anhydride or PA, this material is as a chemical in the production of polyvinyl chloride (PVC) softeners.

Iran Phthalic Anhydride Features

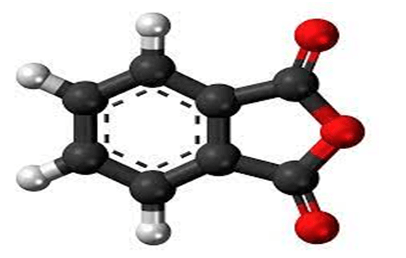

Chemical structure of Iran phthalic anhydride (PA)

Phthalic anhydride (PA) is a white, coarse, or crystalline powder with the following chemical properties:

- Molecular formula C8H403

- Molecular weight= 148.12

- Melting point= 131.1

- Boiling point= 284.5

- Flashpoint= 151 (free), 165 (enclosed)

- Spontaneous flash point= 584

- Density (solid)= 1.527 g / cm3

- Soluble in water, alcohol, ether, benzene, and most organic solvents.

These properties must be taken into account in the process of phthalic anhydride manufacturing.

Phthalic Anhydride (PA) is a cyclic anhydride and an important primary chemical, especially for the production of emollients. Dibutyl phthalate and dioctyle phthalate are important emollients. Phthalic Anhydride (PA) and polyols (such as glycerol, pentaerythritol) can produce polyacrylate resin by the condensate method used in the paint industry.

If an unsaturated acid is condensed with ethylene glycol, the resulting chemical is an unsaturated polyester resin for the production of insulating paints and glass-fiber-reinforced plastics. Phthalic Anhydride (PA) Medicinal is also used.

Chemical structure of PA

Applications of Phthalic Anhydride (PA) in various industries

Iran Phthalic anhydride or PA is primarily used as an intermediate chemical and as a monomer for use in polymer structures. Phthalic anhydride (PA) is widely used in the production of unsaturated polyester resins (UPR), which in turn is used in reinforced plastics for a wide range of applications such as electronics and construction industries, as well as in bathroom fixtures. Pleasure boats and car parts are used.

PA polymeric applications

Its application in the production of alkyd resins is also significant, these resins in turn are used in final products such as paints, varnishes, and coatings. It is used as a raw material for the production of PVC phthalates and softeners for general use and as a raw material in the production of other chemicals such as polyester polyethylenes and saccharin. It is also found in certain pigments and dyes and fire repellents.

PA alkyd applications

The main benefits of using Iran Phthalic anhydride

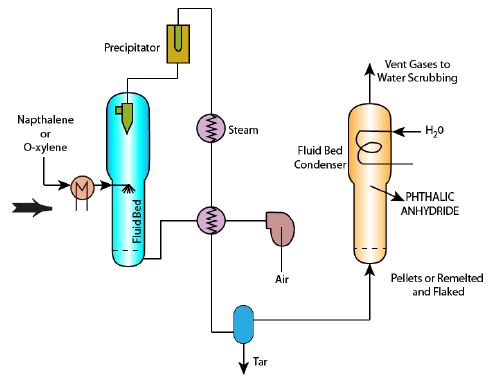

IRAN Phthalic Anhydride manufacturing

The main advantages of the technobel Phthalic anhydride production process:

- High yield of phthalic anhydride (PA): High yield of phthalic anhydride product (up to 115% by weight).

- Lower investment and operating costs: High concentrations of o-xylene in the gas reduce investment and operating costs.

- Complete removal of unauthorized products: Use of reactor post indicates complete removal of undesirable by-products and minimization of phthalic anhydride (PA).

- Optimal heat recovery: Accurate and innovative process design enables optimal heat recovery from reactor gases and the production of medium vapor pressure (MP) and low vapor pressure (LP).

- Use of any suitable oxidation catalyst: Technology design allows the use of any suitable oxidation catalyst on the market.

- There is no fluctuation in the amount of steam exported: Technobel offers Phthalic Anhydride (PA) heat treatment and continuous distillation. Such a plan increases the need for slightly smaller equipment and the greater use of uniform energy sources. There is no fluctuation in the amount of steam exported, which occurs regularly in batch distillation systems.

- Environmental protection: The environment is protected by burning liquid and gaseous pollutants.

- Flexible operation: Fixed bed reactor (s) lead to flexible operation.

- High efficiency: High efficiency of switch capacitors (up to 99.8%).

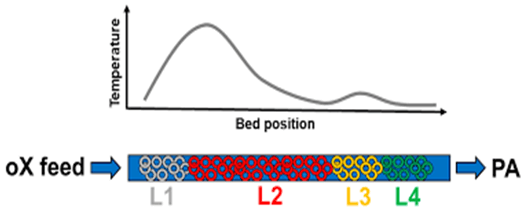

Technobel Phthalic Anhydride production process

Storage and Handling of Phthalic Anhydride

Iran Phthalic anhydride (PA) should be thoroughly sealed in containers and stored in a cool, dry place away from water, acids, strong oxidants, alcohols, amines, and bases. This material must be handled by safety and proper hygiene practices.

Relevant engineering controls including proper exhaust ventilation must be implemented. Inhalation of PA particles can irritate the respiratory tract and cause allergy or asthma symptoms.

Phthalic Anhydride manufacturing and Storing

Phthalic anhydride (PA) is a severe skin irritant, especially for moist skin, and may cause skin eczema. It is also a severe eye irritant and may damage the cornea and conjunctiva. Appropriate personal protective equipment should be used.

Animal studies show that severe exposure to phthalic anhydride (PA) vapor causes congestion, stimulation, and damage to lung cells. There are no studies on the effects of reproduction, growth, or carcinogenicity on the product.

Report on the process of taking Phthalic Anhydride in different periods

About 90% of Phthalic Anhydride consumption is concentrated in three major applications:

- Phthalic Anhydride (PA) Esters: These esters are widely used as emollients for polyvinyl chloride resins.

- Unsaturated polyesters (heat-curable): Unsaturated polyesters have major applications in the manufacture of fiberglass-reinforced components such as boats and tubs.

- Glycerol alkyd resins: Alkyd resins, like phthalates, are widely used for paints.

Since the first release of Phthalic Anhydride (PA) in March 1968 and June 1974, respectively, several aspects of phthalic anhydride manufacturing have changed:

O-xylene is now the main production material, while the use of naphthalene as the starting material has been reduced by about 16% of the total, making it possible to improve the catalyst of smaller reactors.

Advances in equipment and the design of safety devices provide safe operation at higher explosive limits than the desired o-xylene, and now environmental concerns require the addition of an exhaust gas incinerator. At present, almost all Phthalic Anhydride (PA) is carried out by a fixed bed oxidation reactor process with conventional switch condensers that condense Phthalic Anhydride (PA) as a solid.

Iran Phthalic anhydride manufacturing process

Phthalic anhydride production process

Information on the oxidation of o-xylene and naphthalene, the two main processes of phthalic anhydride manufacturing, is updated and analyzed. New techniques for the preparation of catalysts are all based on the saturation method and include the control of parameters such as pH and ionic strength of solutions.

The performance of the resulting catalysts is compared with catalysts prepared by other methods. Sulfur-containing materials and promoters such as AG, P, NB, SB increase the performance of the catalyst. Studies of their effect on the surface, acidic properties, and stabilization of the vanadium oxidation state in V2O5 supported catalysts are described.

Recent efforts to correlate the physicochemical properties of catalysts with their catalytic properties are analyzed. FTIR, Raman spectroscopy, base adsorption, V-NMR, XRD, XPS, SIMS, and electrical conductivity are used in the study of V2O5 / TiO2 catalysts, which make it possible to better understand the effects of properties such as acidity and surface oxidation state. Particular emphasis is placed on the presence of VIV, which is thought to result in less choice of PA.

For oxidation of o-xylene, the formation of inflexible by-products occurs as a secondary reaction, which achieves a weak carbon balance in some experimental conditions. Non-volatile by-products, which are formed in the presence of strong acid sites, can be adsorbed on the catalyst surface, lead to inactivation, or be completely ignited and act as a source of CO2. Attempts to quantify and specify those by-products are described.

Reaction modeling is analyzed using both fixed and liquid bed reactors, including the study of parameters such as inlet temperature and bath temperature. Models are also produced due to catalyst deactivation.

For o-xylene oxidation, inactivation is associated with reversible processes, such as changes in the vanadium oxidation state, deposition of unstable and irreversible compounds, such as structural changes, surface reduction, deposition, and changes in promoter concentration at the catalyst surface.

The study of EUROCAT V2O5 / TiO2 catalysts has been reviewed in several European laboratories and their performance is compared with other V2O5 / TiO2 catalysts.

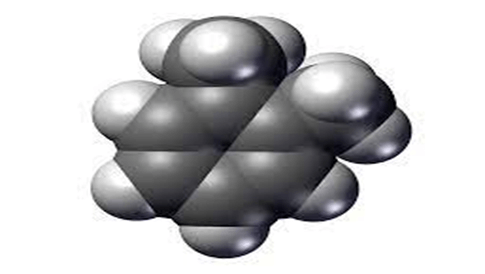

Uses of xylene in global industries

Uses of xylene

Xylene is one of the top chemicals produced in the United States and is usually made from crude oil. The use of xylene is enormous, both in pure form and in compounds. It is widely used in several industries as well as in the fields of dentistry and medicine. But xylene is still the best chemical for tissue processing and dyeing purposes.

One of the main uses of xylene is as a lubricant and hence it is used in engine oil or brake fluid. The strong solvent properties of xylene are used in printing, rubber, and leather processing. Xylene is one of the components of engine oil lubricants, paints and paint thinners, waxes, antifreeze, sealants, adhesives, and even gasoline and cigarettes. Xylene is used in some adhesives. Xylene is also used as a cleanser. Additional uses for xylene include adding it to pesticides and disinfectants.

O-xylene (OX) applications

O-xylene (OX) is one of the three major commercial isomers of xylene. Almost all o-xylene (OX) emissions are used in the production of Phthalic anhydride (PA), which has three main uses: phthalate softeners used in combination with polyvinyl chloride (PVC) resins. Unsaturated polyester (UPR) resins are used in glass-reinforced thermostatic engineering applications and alkyd resins are mainly used for surface coatings.

Small amounts of o-xylene (OX) are used in solvent applications (which are declining) and in the manufacture of bactericides, soy herbicides, and oil additives. It is a high-performance film used in rigid films and packaging where performance requirements are more precise than polyethylene terephthalate (PET) products.

Naphthalate (PEN) is an emerging and potential market that could increase demand for o-xylene (OX) in the future. However, demand for Phthalic Anhydride (PA) has the greatest impact in the o-xylene (OX) markets. The most widely used Phthalic Anhydride (PA) in the manufacture of emollients is mainly dioctyle phthalate, which is used primarily to modify synthetic polymers, primarily PVC.

- Hence, the consumption of Phthalic Anhydride mainly depends on the growth of flexible PVC, which is sensitive to economic conditions due to its use in the construction and automotive industries.

- The second-largest application of PA is in UPRs, which are used to produce fiberglass-reinforced resins. Their main markets – construction, shipping and transportation – are also linked to economic conditions, while UPR growth is offset by saturation of major application areas.

- The third major output is phthalic anhydride alkyd resins used in solvent coatings for architectural applications, machinery, furniture, and appliances. Due to the level limitation of volatile organic compounds in surface coatings, they have a slow trend.

O-xylene

Our technical services provides Iran phthalic anhydride sales!

Our technical service staff has extensive professional experience in the production and sale of phthalic anhydride (or PA) for domestic consumption and export of Iran phthalic anhydride (PA) as well as gaining expertise in the areas of monitoring, helping to set up and optimize catalyst performance.

Through research and development, we shape the future and develop profitability growth. Optimized processes and intelligent system solutions, along with new and innovative products, play a major role in the long-term success of our customers as well as ourselves.

In addition, we are currently in contact with leading universities, research institutes, start-ups, and industry partners, which will further strengthen our research activities around the world. Dear reader, you can contact our experts in the commercial unit to know the price of Phthalic anhydride (PA), receive advice, and buy Phthalic anhydride (PA) in your desired grades.