Which industries are known as the main consumers of polystyrene? As you know, polystyrenes are a kind of aromatic synthetic polymer, which is based on a chemical material called a “styrene monomer”.

Polystyrene is one of the petroleum-derived products and liquid hydrocarbons, which has a flexible structure. This material melts at high temperatures.

Polystyrene consumers

Consumers of polystyrene

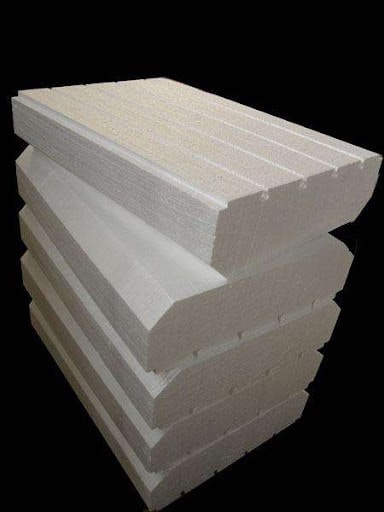

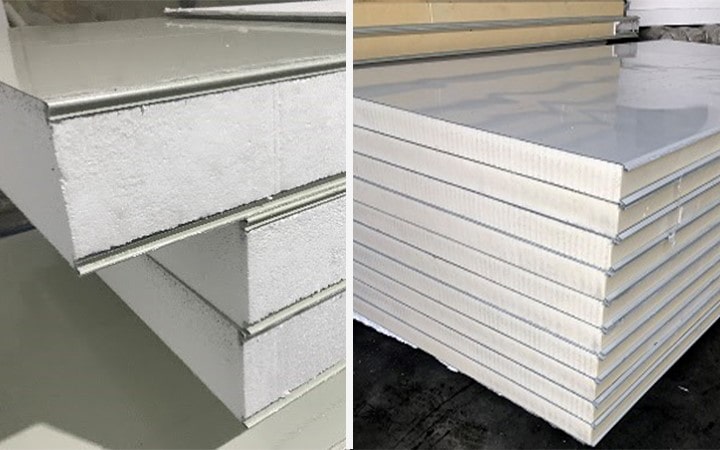

Making a sandwich panel:

One of the most important consumers of polystyrene is the manufacturers of sandwich panels. The reason for using this material in panels is its sound and thermal insulation capability, which is used in the construction of various types of wall and ceiling panels.

Another reason for using polystyrene in the construction industry is its high durability, lightweight and insulating ability. Polystyrene is a low-cost material that is used to insulate various buildings.

Consumers General Purpose Polystyrene (GPPS):

This type of polystyrene is known in the Iranian market as “crystal”. This type of polystyrene is often used for general use; Due to the ease of processing that exists in this material, which is due to its amorphous structure.

This type of polystyrene has a very desirable appearance, which makes it suitable for various applications such as dielectric materials. The high strength of this material has made the manufacturers of sensitive devices and consumers of polystyrene willing to use it in the packaging of sensitive materials.

This material is used as a suitable option for pharmaceutical packaging and making the body of different watches, making different types of disposable containers, using it for packaging special products such as compact discs that require high care. One of the most important uses of this type of polystyrene is its use as a cooling insulator in the body of refrigerators.

Consumers of High Impact Polystyrene (HIPS):

This type of polystyrene has a very high resistance that makes it used in any type of plastic object. This material is called “HIMPAC”. Usually, sports equipment manufacturers use this type of polystyrene to cover sports equipment.

Currently, one of the new decisions to use “HIMPAC” is to use it as a protective layer for sandwich panels so that they can greatly increase their strength.

One of the most important uses of Hypep is its use in the manufacture of plastofoam blocks, which are known today as the best alternative to cement blocks.

Consumers of Expanded Polystyrene (EPS):

This type of polystyrene is available in white color and its most important feature is its fire resistance or fire resistance. This type of polystyrene is known as ionolite and is added to it when making a volumizing foam.

The most important consumers of this polystyrene model are manufacturers of sandwich panels and manufacturers of various types of sheds.

Notable characteristics of this type of polystyrene are the possibility of high impact absorption resistance, heat resistance, and low conductivity against heat. These features have made it very popular in various industries for use in packaging and insulation.

Consumers of expanded polystyrene

Consumers of extruded polystyrene (XPS):

This material is known as a type of plastic that is supplied as a high-density foam material. This type of polystyrene is made of polystyrene polymer using the extrusion process, therefore, it has a rigid and relatively rigid structure, which makes it very popular in the insulation industry.

This polystyrene is used to make a wide range of products, the most important of which is the production of building materials and the manufacture of refrigeration panels and other types of panels.

One of the most important uses of polystyrene in recent years is its use in construction.

This product is supplied in the form of polystyrene blocks, which has attracted a lot of attention from consumers of polystyrene. The reason is its lightweight and low cost. In the past, cement blocks were used to build different types of roofs, which are very heavy in weight.

Polystyrene blocks have a very low weight, which greatly reduces the dead load of the building, which makes it more resistant to earthquakes. Fast implementation, easy transportation, and cost reduction make polystyrene roof foam very popular.