In many cases in plastics, unlike rubbers, the product should not be easily stretched or deformed. To know how resistant materials are to deformation, a quantity called a modulus is measured. Modulus is generally the resistance of a material or product to deformation. There are different types of modules in polymers and plastics, including tensile modulus, torsional modulus, shear modulus, and flexural modulus. In this article, we will standardize with Flexural modulus and its measurement method in High Impact Polystyrene (HIPS).

Flexural modulus

Flexural modulus Test

Flexural strength, also called fracture modulus, rupture modulus, and elasticity. It is a property of the material and indicates the maximum amount of compressive or tensile stress that the test material can withstand in the flexural test before failure. In other words, flexural strength indicates the highest amount of stress tolerable by the material before the breaking point.

Mathematically, the slope of the stress-strain curve is also measured in units of force on the surface (Newtons per square millimeter).

Modules of plastic materials such as High Impact polystyrene (HIPS) are very important due to the effect on mechanical properties in the correct choice of materials and also to design products for various uses. Awareness of it can save the material production process economically.

Parameters affecting the flexural modulus

The flexural modulus in a substance is strongly influenced by the binding energies of its atoms. The stronger these forces, the higher the flexural modulus of elasticity of the material. Finally, it increases the melting point of the material.

If we increase the temperature of the material, the motion of its molecules will increase, and increasing these movements will reduce the energy required to separate the molecules from each other, and as a result, the amount of flexural modulus of the material will decrease.

Standard flexural modulus measurement test

The standard flexural modulus (elasticity) test generally measures the strength of a material against deformation in the flexural state. This is usually true for materials that are rod-shaped (with a cross-section in the shape of a circle) or rectangular. In this test, almost all the details of the resistance of the sample against flexural forces are evaluated.

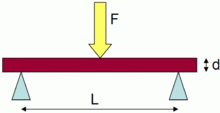

The flexural test is performed in two ways, three-point, and four-point, by the tensile testing device. The most common type for HIPS samples is the three-point test.

In this test, the device software plots the amount of force applied and the amount of bending of the HIPS specimen in a graph. In it, the vertical axis represents the tensile force and the horizontal axis represents the amount of flexure or the same strain.

The method of this test is performed by ISO 178 and ASTM D790. To perform the test, the sample must first be prepared by machining and cutting the product or injection molding. The length of the rectangular sample should be 20 times the thickness and its width varies depending on the thickness.

For example, if the thickness of the sample is between 1 and 3 mm, its width should be equal to 25 mm, and if the thickness of the sample is between 3 to 5 mm, the width of the sample should be equal to 10 mm.

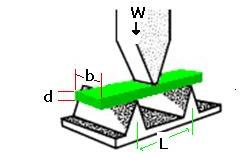

- Then, the sample is placed on two holders with a distance of 16 times the thickness of the sample and in the center of them as shown below.

- The diameter of the supports should be 4 mm for samples less than 3 mm thick and 10 mm for samples with a thickness of 3 to 5 mm.

- The diameter of the force input lever to the sample in the test is equal to 10 mm.

- After placing the HIPS sample in the indicated location and entering the sample dimensions in the software, the jaw of the device goes down at a speed of 1 mm per minute and flexing the desired sample.

This test method is called three-point flexing because in this method, two supports are considered as two points and the third point is the point of contact of the sample with the force input lever.

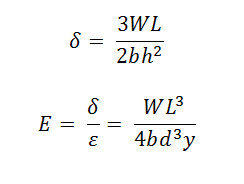

After the specimen is subjected to flexural force, the amount of modulus and the amount of flexural strength are tested according to the dimensions of the specimen. Then the applied load can be calculated through the formula presented below or the stress-strain curve.

Flexural modulus formula

Flexural strength

E: flexural modulus

W: the force applied

d: Sample thickness

b: Sample width

L: The distance between the two locations of the sample on the device