The strength of polymers indicates only the force required to break. This cannot show the changes that occur during the experiment, for example. Therefore, it is necessary to study the behaviors of the polymeric material such as elongation in the sample. Elongation is a kind of deformation in a stressed sample. In this article, we will get acquainted with the concept of elongation as one of the mechanical properties of High Impact Polystyrene (HIPS) and how to measure elongation at the breaking point of High Impact Polystyrene.

What is elongation?

In a tensile strength test to measure the mechanical properties of polymeric materials, including High Impact Polystyrene (HIPS), the polymer sample is deformed by stretching. Then its length is increased, which is called elongation. The percentage increase in length is equal to the length of the sample after being drawn, divided by its initial length multiplied by 100.

The ultimate elongation for each type of polymeric material indicates the amount that the sample can be pulled before its breaking point. Reversible elongation is also the percentage of elongation that can be achieved without permanent deformation of the specimen; This means that after removing the stress, the sample quickly returns to its original length. Measuring this value in elastomeric materials is very important.

Hard plastics in tensile testing do not change much with increasing stress, resizing or strain, and do not deform much. The deformation of these plastics is elastic and they withstand the stress until they fail to the maximum.

Flexible plastics fall into another category. These types of plastics work elastically by applying stress to the deformation area to reach the yield point. After reaching the breaking point, as the amount of stress increases slightly, they change the size to reach the breaking point.

Tensile test

A tensile strength test is a test that puts the sample under a tensile force until it reaches the breaking point. The increase in length is also recorded simultaneously with the force or load applied. The results of this test can be used to control the quality and predict the behavior of a substance under the influence of various forces.

Elongation test

By performing this test, the stress-strain curve of the polymer material, which shows the behavior of the material under tension, can be plotted based on the values of the applied force in terms of elongation.

In most tensile tests, it is observed that in the early stages, there is a linear relationship between the applied force or load and the increase in sample length, and the stress is proportional to the strain.

In this area, the diagram follows Hooke’s law, in which the stress-to-strain ratio is a constant value called the “modulus of elasticity” or “Young’s modulus”.

The modulus of elasticity is a measure of the hardness of a material and applies only to the linear region of the curve. At a point where the curve is no longer linear and deviates from a straight line, Hooke’s law is no longer applicable and permanent deformation occurs in the sample.

This point is called the elastic limit. From this point on, in the tensile test, after increasing the load or force, if the load is removed from the sample, the material will not return to its original condition before applying force.

During the tensile test, the amount of elongation of the sample under the tensile test can be obtained. This value can be obtained by measuring the absolute amount of change in length or a relative measure of change in length, also called strain.

The amount of strain can be expressed in two different ways: engineering strain and real strain. Engineering strain is obtained from the ratio of length change to initial length and is independent of the geometry and shape of the part. The real strain is similar to the engineering strain, except that it is determined based on the instantaneous length of the sample.

How to do a tensile test

The elongation test, also known as the tensile test, can be performed according to ASTM D638 for High Impact Polystyrene Copolymer (HIPS). In this test, at least 5 specimens must be tested and the preferred size of the specimens is a rectangular strip with a width of 10 to 25 mm and a length of at least 150 mm.

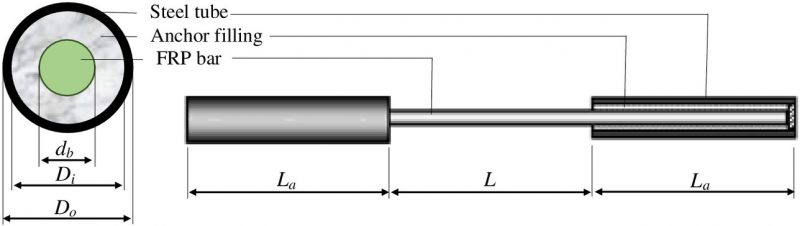

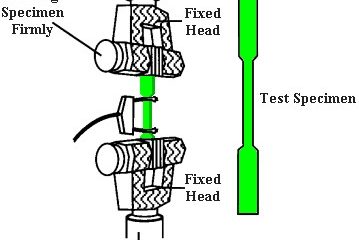

The device required for this test is a traction device that has 2 jaws or clamps. These jaws can change depending on the type of test and its material. The initial distance between the clamps or jaws of the device is 100 mm.

Speciman

Samples must be secured inside these jaws. The lower jaw of the device is fixed and its job is to hold the specimen firmly. In addition to holding the specimen, the upper jaw of the device moves the specimen by pulling it upwards and applying tensile stress to it.

After closing the specimens and tightening them and making adjustments on the traction device software, the device is commanded to subject the specimen to a certain speed (usually 50 mm / min) with different amounts of tensile stress. The sample is stretched until it fails.

In the end, after the sample reaches the breaking point, the force required to create the elongation is reported and the force curve is plotted accordingly; Because the device software, in which the full dimensions of the sample have already been entered, can calculate the strain and elongation at the breaking point according to the formula.

By performing the necessary calculations, the stress curve in terms of engineering strain can be extracted from the initial curve.