What do you know about the differences and similarities between HIPS and GPPS? Polystyrene or PS is one of the most popular thermoplastics in the world. Depending on the function of these materials, people may want to use HIPS (High Impact) polystyrene or GPPS (General Purpose) polystyrene.

Each type of polystyrene has its characteristics that people should research the polystyrene based on their needs and project and choose the model they want. Following the differences and similarities between HIPS and GPPS, it should be said that both of these materials are considered low-cost and cost-effective products. Of course, GPPS or General Purpose polystyrenes are more economical.

Differences and similarities between HIPS and GPPS

Investigate the differences and similarities between HIPS and GPPS

As you know, there are differences and similarities between these two materials, which we will examine in the following. In terms of differences, GPPS or General Purpose polystyrenes are less impact-resistant and have less dimensional stability compared to HIPS.

Another difference between HIPS and GPPS is that High Impact polystyrene has a thin, transparent blue edge. General Purpose polystyrene has received a lot of attention in the industry due to its glass-like properties. It does not affect food and it can be easily molded into various shapes.

What do HIPS and GPPS have in common?

The following are the differences and similarities between HIPS and GPPS. These two materials have common features that include:

- Both are available as hard and low-cost resins.

- These products have a simple function in production and processing.

- Another feature of these two products is FDA compatibility, which makes them widely used in food packaging and kitchen utensils.

- These types of styrenes can be processed by thermoforming, extrusion, pneumatic, injection molding methods.

- Another feature of these two types of styrene is the ability to recycle and use in health applications.

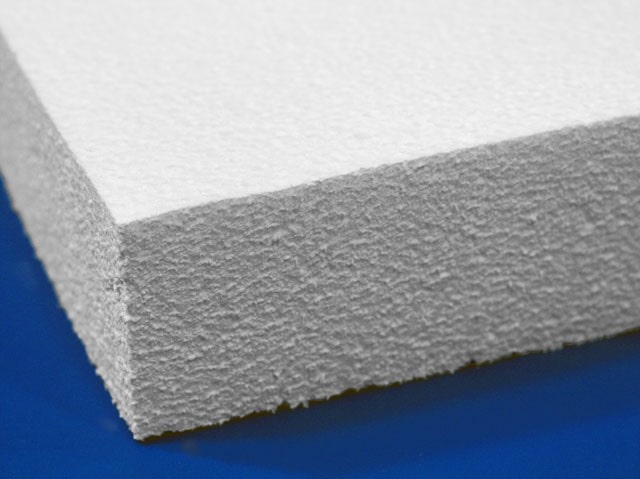

Unique features of General Purpose polystyrene

Continuing the topic of differences and similarities between HIPS and GPPS, we intend to examine the properties of General Purpose polystyrene. This type of polystyrene is made by synthetic polymer methods. The current industry currently uses bulk polymerization and suspension for polystyrene with conventional applications.

The product that is produced based on this process has the following features. GPPS is soluble in chlorinated and aromatic hydrocarbons, esters, and aliphatic ketones. This material is resistant to the action of some organic acids, alkalis, mineral oils, and salts.

It has a low absorption capacity against water.

General Purpose polystyrenes retain their dimensional stability and mechanical properties in wet conditions.

It has electrical capabilities and is non-toxic.

The most important disadvantage of this type of polystyrene is its low impact and heat resistance; So they are only used at low temperatures and low loads.

GPPS

Features of High Impact or HIPS polystyrene

This type of polystyrene is a low-cost and hard plastic material that is easily heated and recyclable. This product is much more durable than General Purpose polystyrenes. This material is made by combining two materials, polybutadiene and polystyrene. To make this type of polystyrene, they use a manufacturing method called extrusion.

This material is known by the acronym HIPS, whose structure is made of a kind of bonded polymerization. The most important features of this product are high flexibility and extraordinary impact resistance. The products produced by this polystyrene have unique elastic capabilities that we cannot see in standard and General Purpose samples.

The material used in this type of polystyrene can withstand impact and high pressure. It also can be fragile. The reason for naming this type of polystyrene as High Impact is its high impact resistance. This model of polystyrene is considered one of the oldest thermoplastic models in the world. This material is made by monometric polymerization.