As you know, phthalic anhydride is known as an industrial chemical and is considered as one of the first dicarboxylic anhydride acids with divalent potential. In phthalic anhydride production, o-xylene is mixed with hot air and led into a reactor with tubes containing catalyst and crude phthalic anhydride. After this process, the material is cooled in a condenser and reheated after phthalic condensate and enters the vacuum suspension system. In this way, a high-quality product is produced based on the process described below. Finally, phthalic anhydride is stored in liquid form or white flakes in special tanks.

Oxidation unit of the phthalic anhydride production process

Stages of phthalic anhydride production

In this part of phthalic anhydride production, the filtered air is subjected to compressed pressure and after heating, it is evaporated by steam and enters the mixer. The stored o-Xylene enters the evaporator after performing a quality control process using a preheating converter.

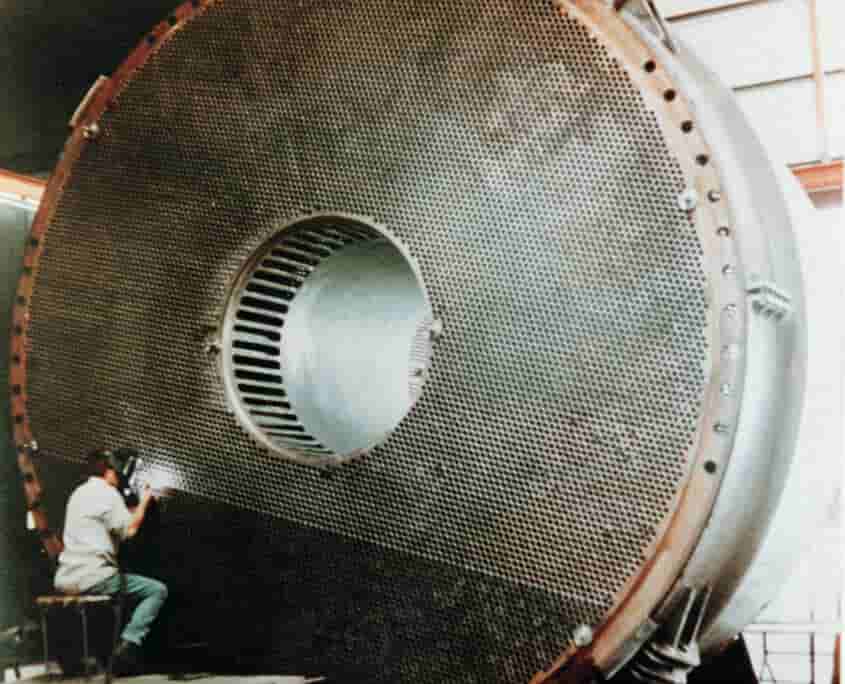

o-Xylene is injected into a stream of hot air and, after reaching the ideal position, it is introduced into the oxidation reactor in the presence of air. At this stage, it is necessary to control the flow and temperature of o-xylene very carefully. In the case of the oxidation reactor, it must be said that it has a stable and acceptable substrate. Inside the reactor, there are shells with several vertical tubes that are carefully filled with catalysts such as titanium dioxide with vanadium pentoxide and an activator.

The second stage of the phthalic anhydride production process

At this stage of the production process, we observe that a mixture of air and o-Xylene is passed through the catalysts. The result of this reaction is the production of gases that are transported out through the end of the chamber.

This reaction occurs in the exothermic gas phase; Therefore, they neutralize the heat generated by the reacted gases. To do this, they use molten salts that are present on the outside of the reactor shell. Catalysts with maximum activity and high resistance are used to create the minimum pressure drop.

The protection of these catalysts is done by special ceramic rings. To stabilize the controllers, they use precision tools to ensure the safety of operations and equipment.

The third stage of the phthalic anhydride production process

phthalic anhydride

A large portion of the phthalic anhydride present in the reaction gases is obtained by refining. This separation process is done with the help of special equipment. This equipment includes tubes that contain special warming oils. The temperature control of this equipment is done by ventilation in closed loops. These devices are known as condenser switches.

In this system, the temperature of the exhaust gas is kept relatively constant and the oil temperature is set optimally to achieve the maximum product recycling. An automated control system is used to control processes and operations.

After these steps, the crude phthalic anhydride, which is in the molten state, is transferred to a heated tank. It is then transferred to a refining unit. Here, the exhaust gases, which contain small amounts of maleic anhydride and phthalic anhydride, are transferred to a catalytic combustion chamber, along with other by-products such as monoxide and carbon dioxide.

To provide the best quality phthalic anhydride to consumers, phthalic anhydride is recommended to create thermal stability and color of the product before distillation. During this process, the amount of residence, heat, and temperature during the preliminary heat treatment is strictly controlled.

To prevent air pollution during this process, a small purification column and a system for air suction are prevented.

After the heat treatment operation was performed. The phthalic anhydride is transferred to a storage tank and then transferred to a vacuum unit, where the process of obtaining pure phthalic anhydride is performed.

During this operation, a continuous distillation column is used to separate the phthalic anhydride from the overhead material and transfer it to the storage and flake section. During phthalic anhydride production, great attention is paid to the quality and color of the product.