Polystyrenes are molded to suit different applications. The most important uses of polystyrene are in compact discs, packaging, and home appliances. The properties of this material make it suitable for molding and it can be used with the same texture.

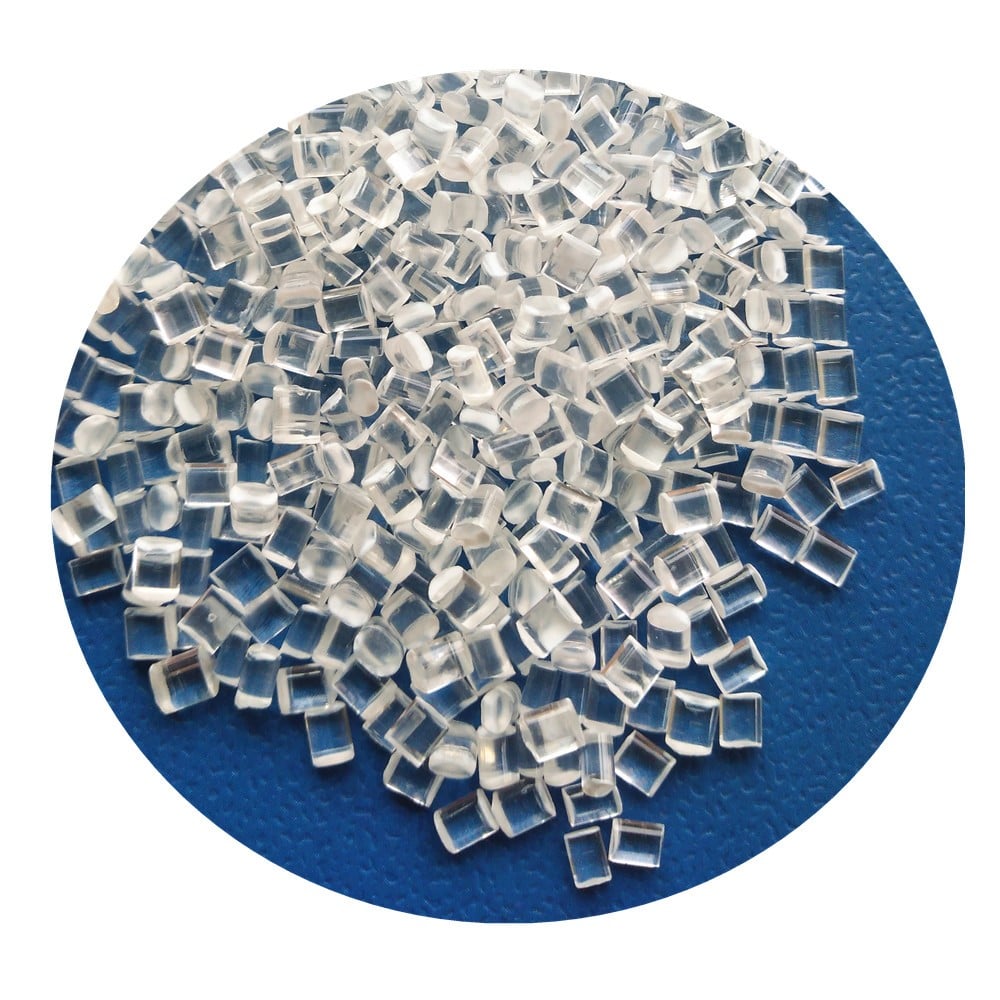

With simple polystyrene mold, styrene can be used for a variety of purposes. Smooth shrinkage allows it to be carefully inserted into molds and extruded. Polystyrene is a normal transparent or crystalline material that can transmit light up to 90%.

GPPS Mold

Features of High Impact Polystyrene

This material is sensitive to physical impact and is therefore suitable for impact. By adding rubber material, it will have impact-resistant properties and at the same time, its tensile strength and stiffness will be reduced. This substance is known as an anti-shock chemical (HIPS).

General Purpose (GPPS) polystyrene is less resistant than impact-resistant polystyrene and is used in everyday materials and commodities.

Properties of polystyrene

Although this material is suitable for blocking ultraviolet rays and staining, it is not recommended for outdoor use. Of course, limited use outdoors is better, but it is suitable for indoor use.

Polystyrene is acid-resistant to alkalis and chemicals but is vulnerable to organic chemicals. Crystalline polystyrene is resistant to temperatures of 68 to 93 degrees Celsius. The tensile strength of these materials is between 5,000 and 7,000 psi and in impact polystyrene, it will be 2.5 lbs/ft.

The flexural modulus of the crystal polystyrene is 450,000 psi, and this value is reduced to 25,000 psi in impact-resistant polystyrene. This module indicates the hardness of the material, and the higher the numbers, the stronger the material.

Secondary operation of polystyrene mold

These molds can be done in any way to get them out of the mold. Different tasks can be done according to the template.

Polymers can be found everywhere. Various materials such as textiles, electrical appliances, medicine, food, chemicals can be seen. The properties of polymers are repeated in polymer structures. Nylon bags and plastic bottle caps are made of polymeric materials. This material has a styrene monomer.

The structure of polymers is different from each other and when they are connected, they form a polymer chain.

Efficient polystyrene molds

Properties of polystyrene plastic

The mechanical and thermal properties of this material are very important. By heating, the shape of these materials can be changed. Once formed, the material is cooled and can be extruded. Thermoplastics can be produced in this way. Different materials can be produced by injection molding.

With these materials, different types of products can be produced, and in some cases, even some vehicle parts can be produced. Thermoplastics, thermostats, glass, and metals are produced by this method.

Thermoplastic injection molds melt at a certain temperature. In this way, plastic materials can be made under less pressure. On the other hand, plastic materials must be made in such a way that they are also resistant to cutting.

By melting raw materials and molding in different molds, different plastic materials can be made. Melted materials must have a good flow to be able to design different quality plastic materials. With these characteristics, plastic materials will have a uniform structure and texture.

The properties of plastic materials can be measured in different ways. Melting temperature and degradation is important in the quality of plastic materials. Some features can be identified by summing up other features. Adhesion is one of the most important properties that can be obtained by summing up other properties.

Temperature control plays an important role in molding polystyrene. Temperature sensors are installed in different parts of the product mold and control the temperature. Some manufacturers produce their products at the same temperature.

Determinant parameters change when working with plastic materials. For example, polystyrene parameters are different from High Impact styrene. In the production of each plastic material, production conditions and parameters change. Especially the melting temperature is different.

A Conclusion from the polystyrene mold article

Polystyrene is used to produce plastic materials. It is transparent or crystalline and can transmit light. Plastic materials are resistant to tension and hardness.

Production factors and especially melting temperature have a great impact on the properties and properties of plastic materials and production planning can be changed according to the different plastic materials that need to be prepared.

Controlling various factors such as temperature at each stage of production is important and it is necessary to pay attention to the molten material that is placed in the molds to finally produce a quality product.