Polystyrene resin is one of the most well-known rubbers and plastics that exists in different types. Each polystyrene resin has different uses. Different industries use polystyrene resin for their purposes and also these plastic materials have a very wide range.

Types of polystyrene resins

Acrylonitrile butadiene styrene (ABS)

These polystyrene resins are made from a combination of acrylonitrile, butadiene, and styrene. Different types of polystyrene resin can be prepared with different compounds of acrylonitrile, butadiene, and styrene. In addition, other compounds can be created with polyvinyl chloride compounds, polycarbonates, and polysulfones. Thermoplastic can be produced by processing acrylonitrile butadiene styrene.

Applications:

- Electronic components

- Auto Parts

- Home Appliances

- Enclosures

- General-purpose goods

- Car interior parts

- Car exterior parts

- Medical Goods / Health Care Goods

- Construction goods

- Home appliance components

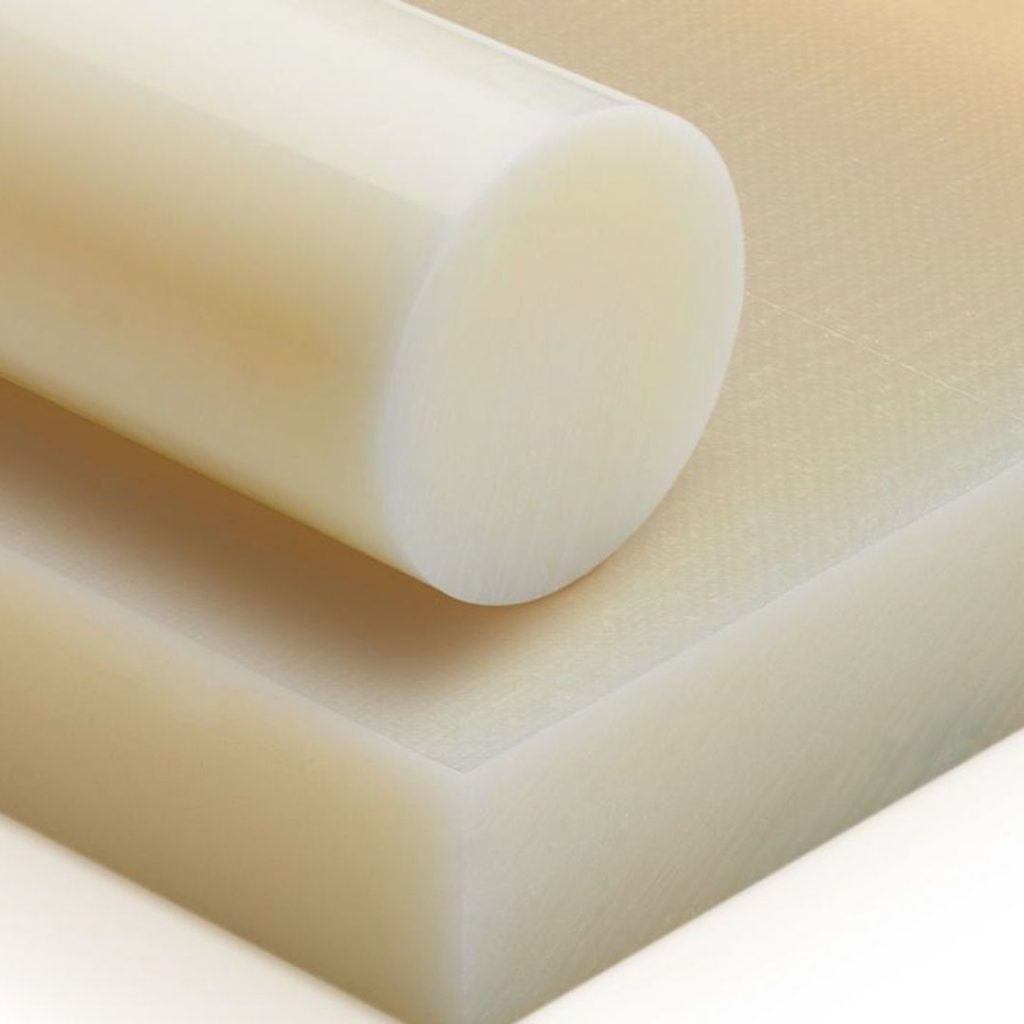

Acetal (POM)

Thermoplastic is a polystyrene resin that is produced by the additional polymerization of the chemical raw materials of aldehydes and the carbonyl reaction. Acetal resins are very strong and resistant to moisture, chemicals and have very good electrical properties. Due to the strength of these materials, they are even better than nylon materials. These resins are produced by molding. These materials can be used in mechanical and industrial products.

Applications:

- Auto Parts

- Gear

- Ball bearings

- Engineering parts

- Container

- False Ceiling

- Industrial goods

- Electronic components

- General-purpose goods

- Car electronics circuits

Acrylic (PMMA)

Acrylics are mostly produced from methyl methacrylate (PMMA) polymers. Acrylics are produced in powder or liquid form. Bright and shiny acrylic products are produced that light passes through these materials. These materials are used to light or extinguish fires. It never produces toxic gases and is resistant to air, wind, and ultraviolet rays. Acrylic is the best alternative to glass.

Acrylic (PMMA)

Applications:

- Auto Parts

- Lighting accessories

- Medical Goods / Health Care Goods

- Industrial Parts

- Monitors

- Light bulbs

- Lighting devices

- Types of enclosures

- lens

- All lighting fixtures

Cyclic olefin copolymer (COC)

COC resin is a type of polyethylene chemical and is very transparent, which is used in many industries and many cases makes it superior to others.

Packaging: Labels and membranes, durable packaging, easy-to-open packaging, torsion packagings such as cellophane, cosmetics, and bottles.

Medical care: medical equipment, serum, syringe, medicine, wound adhesive, tray making, wearable gadgets

Medical diagnosis: microfluidics, microplates, therapeutic care, ultraviolet transparent plates

Electronics: Antennas and capacitor membranes

Polybutylene terephthalate (PBT)

This thermoplastic material is polystyrene resin used as insulation in the electronics industry. This material is also flame resistant and can be produced in crystalline molding.

Electrical, chemical, thermal, and constant size and resistance to bending, traction, and static electricity make thermoplastic excellent.

Polybutylene terephthalate (PBT)

Applications:

- Projector

- Medical Equipment

- Door and window parts

- Home appliance parts

- Fiber optic cable

- Electronic components

- Auto Parts

Polyamide (PA)

This thermoplastic material produces all types of nylon that are used in many industries and are very resistant to gases and chemicals.

Polyamide

Applications:

- Auto Parts

- Electronic components

- Industrial applications

- Engineering parts

- connections

- Enclosures

- General-purpose goods

- Sports products

- Power supplies

- Other tools

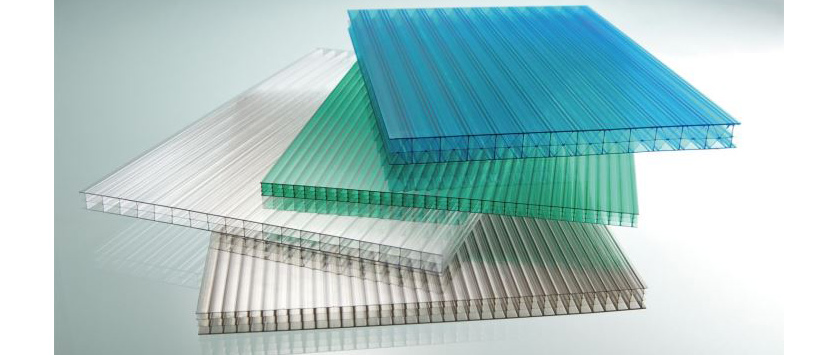

Polycarbonate (PC)

This polystyrene resin is compacted by the polymerization and is very strong. Many industries tend to use this material to make bulletproof glass, anti-brittle lenses, CD / DVD, due to their fire resistance.

Polycarbonate (PC)

Applications:

- Electronic components

- Display screens

- Lighting accessories

- Auto Parts

- Home Appliances

- Medical Goods / Medical Care

- Building Materials

- Container

- General-purpose goods

- Car interior parts

Polyketone (aliphatic)

This is a semi-crystalline polystyrene polymer resin that has very high strength. This material is resistant to tension and wear and is made by molding. Nylon and polyester are made with this material.

Applications:

- Auto Parts

- Engineering parts

- Industrial products

- Electronic components

- Gear

- Connections

- Food packing

- Cosmetics packaging

Polypropylene (PP)

The properties and characteristics of this chemical are known and it has many applications.

Polypropylene (PP)

Applications:

- Auto Parts

- Home Appliances

- Electronic components

- Industrial goods

- Packaging containers

- Car interior parts

- Electrical / electronic components

Polystyrenes

high impact polystyrene (HIPS) and General Purpose Polystyrene (GPPS)

This polystyrene resin is transparent and inexpensive and can be used in many industries.

Applications:

- Packing

- Plastic sheets

- General-purpose goods

- Foam

- Electronic components

- Home Appliances

- Toy

- Home appliance parts

- Packaging containers

Polyphenylene ether (PPE)

The combination of this material with polyamides creates strong goods.

Applications:

- Electrical / electronic components

- Electronic screens

- Home Appliances

- Building Materials

- Auto Parts

- Car interior parts

- Parts under the hood

- Electronic components

- Electronic circuits

- Lighting accessories

Other resins

- Polyacrylic acid

- PVC

- Polyester amid

- Polyethyl sulfone

- Polyethylene terephthalate

- Polyphenylene sulfide

- Semi-crystalline thermoplastics

- Polyfetal amide

- Moldable plastics

- Acrylonitrile styrene acrylate

- Acrylonitrile styrene

- SMMS or MS resins

- Anti-UV plastic resins

- Thermoplastic elastomers

- Polymeric compounds

- Thermoplastic elastomers

- Thermoplastic resins

Conclusion

There are different types of polystyrene resins. This material is used in automotive, electrical, home appliances, packaging containers, home appliances, medicine, general-purpose goods, building materials, equipment, and sports equipment. In addition, it is used in the production of engineering parts, automotive and technical parts of automobiles, toys, toilets and baths, cosmetics, and food industries.

The applications of using these plastic resins are increasing every day. But it is hoped that the day will come when humans will use a natural rubber that is not harmful to human health and the environment.