There are several methods for polystyrene recycling and this chemical is used in many industries. Concerns about contamination and disposal of this chemical have led to the development of methods for recycling polystyrene. Crushing and dissolving are recycling methods and make it possible to reuse this material.

Polystyrene recycling methods

Melting down

Styrene can be melted and recycled with special ovens. Polystyrene is recycled according to the needs of the ovens. In these devices, polystyrene returns to its original size by removing excess air inside the grains. Polystyrene has a lot of oil that is sold to diesel refineries to supply diesel fuel. Other uses of chemicals or organic fruit compounds called limonene, which is a polystyrene solution without the use of recycling ovens.

Polystyrene recycling methods

By recycling foam, new packaging and insulation products can be produced. Recovery companies crush polystyrene blocks and combine them with concrete to improve the properties of these building materials. Recycling destroys the properties of this material; Therefore, it is used to insulate buildings and houses.

In some cases, polystyrene recycled materials are turned into sheets that can be used to insulate buildings and homes. By recycling polystyrene, building insulation panels can be provided.

Melting and molding

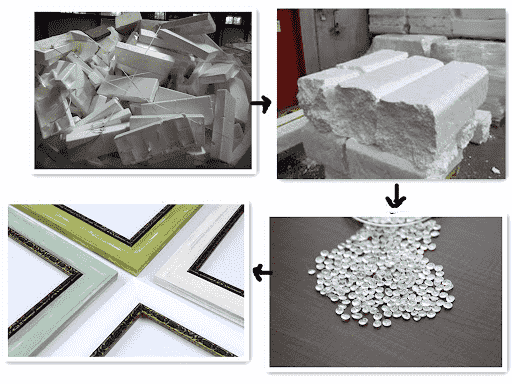

In another method for polystyrene recycling, this chemical can be poured into molds and new goods can be produced. By recycling, benches, paintings, and some household goods can be produced. Recycling polystyrene means that manufacturers do not look for other raw materials. Recycling can be used to make alloy metals or other molded goods.

By recycling polystyrene, other goods needed by consumers can also be provided. Even with the recycling of polystyrene, all kinds of retail goods can be supplied. In many countries, new goods and products can be produced by recycling polystyrene; Therefore, by disposing of this chemical, damage to the environment is prevented.

Melting and molding methods

Recycling of polystyrene and reuse of carton packaging

Recycling can produce new packaging that many companies use to package products. Many companies today recycle and reuse packaged cartons.

The recycling rate is 27% and the rest is discarded. Polystyrene carton packages are less recycled and used. By recycling high impact polystyrene (HIPS) and general purpose polystyrene (GPPS), new goods can be produced and used.

Recycling extruded and expanded polystyrene

Extruded and expanded polystyrene can be used to produce new products that are used in many industries.

In recycling, discarded goods and products are thrown in the trash, shredded and raw materials are dumped into machines. From these materials, expanded and extruded polystyrene or other goods required by industry can be supplied.

PS Recycling Companies

For polystyrene recycling, special devices are used and each device is used for recycling polystyrene blocks and sheets.

Reasons for Polystyrene recycling

Polystyrene is one of the most well-known thermoplastic materials with a transfer temperature above 100 ° C. This substance is difficult to decompose and therefore can pollute the environment. Many needs can be met by foam recycling.

The reason for reducing the volume of recycling

Recycling polystyrene is done in different ways and today many recycling companies do not have the necessary government incentives to do so. Therefore, a small amount of polystyrene is recovered and polystyrene foam is seen in small amounts and densities in the waste. Recycling is not cost-effective in many ways. That’s why recovery companies get a small amount of polystyrene. But recycling polystyrene foam is a business that has a lot of potentials and can be developed and expanded.

The recycling industry is developing and it is necessary to make the necessary investments in this industry to increase the amount of recycling from 30 kg to 400 kg. New methods can be found for polystyrene recycling so that it can be done faster and with more cost-effective methods.

Conclusion

By recycling polystyrene by melting, smelting, and molding methods, new products, and goods can be produced. This chemical decomposes over more than 500 years; So recycling is better in many ways, recycling methods are not cost-effective at the moment. It is necessary to make the necessary investments in this industry so that recovery companies are willing to do so.