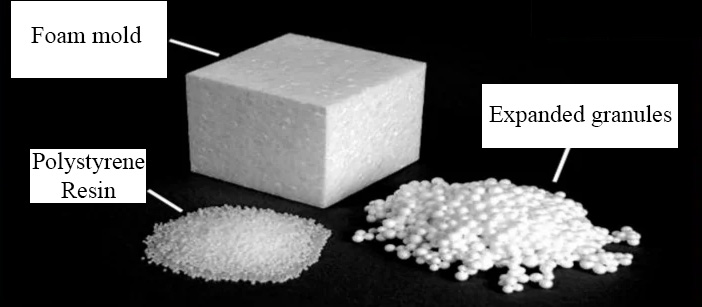

Expanded polystyrene is made of white polystyrene beads and is used for packaging, insulation, and other items. It is made of styrene and pentane. EPS is made from polystyrene beads, but extruded polystyrene is made from the crystalline beads of this material. Water can destroy the insulating properties of EPS, but extruded polystyrene is durable and resistant to environmental factors. For this reason, this type of polystyrene is used in construction.

How to make expanded polystyrene

EPS is designed and manufactured in three stages: pre-expansion, growth, stability, and molding. Polystyrene is made from crude petroleum products. Expanded polystyrene is made with pentane foam solvent. Polystyrene beads are pre-foamed at temperatures above 90 ° C. This temperature causes the pre-foam solvent to evaporate and swell 20-50 times its original size. Polystyrene beads are stored for 6-12 hours to return to pre-changed condition.

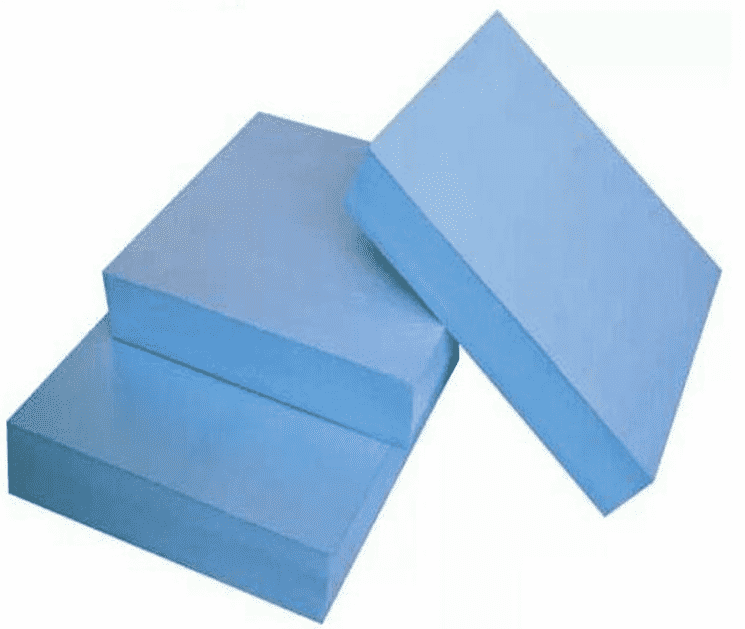

Extruded polystyrene

Extruded polystyrene is produced by the extrusion process. Plastic resin and other materials are melted and poured into molds and taken out of the mold after cooling and freezing. This type of polystyrene is the best insulation and is resistant to moisture and static load. In some cases, it is even used as building insulation.

Expanded polystyrene and extruded polystyrene differences

The first difference is the production method of expanded and extruded polystyrene from polystyrene beads. EPS is strong, and has light insulation. Extruded polystyrene is also durable and strong.

EPS is made from a thermoplastic material made from polystyrene granules. While extruded polystyrene is made of polystyrene crystals. Expanded polystyrene has the least negative impact on the environment compared to extruded polystyrene.

Definition

EPS is a thermoplastic material made from polystyrene beads, but extruded polystyrene is made from polystyrene crystals.

Expanded polystyrene and extruded polystyrene differences

Raw material

Expanded polystyrene is made from solid grains of polystyrene, while extruded polystyrene is made from crystals. In the production of extruded polystyrene, resin and other materials are used, but in expanded polystyrene, the grains of this material is used.

Production Process

The heating of gas-containing polystyrene beads produces expanded polystyrene. But extruded polystyrene is made by removing the liquid molten polystyrene mold, which is cooled and thickened in the molds.

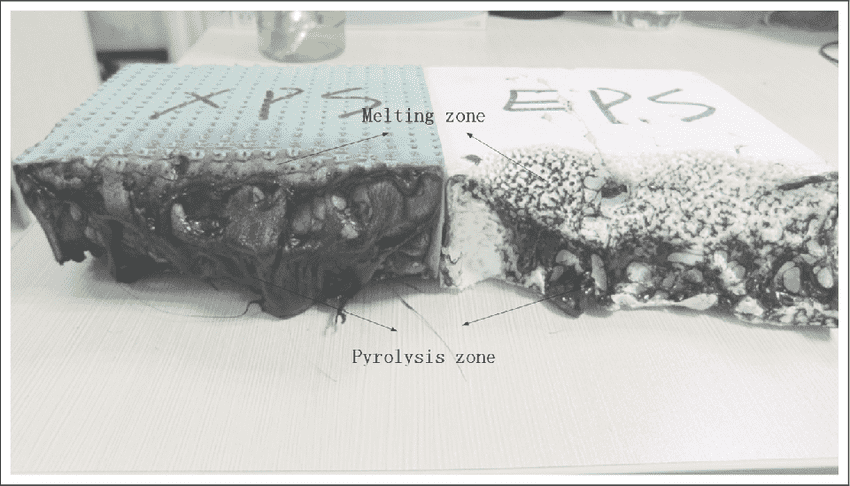

EPS and XPS

Impact on the environment

Expanded polystyrene has had the least negative impact on the environment. On the contrary, extruded polystyrene has the most negative impact and destroys the environment.

Introduction of applications

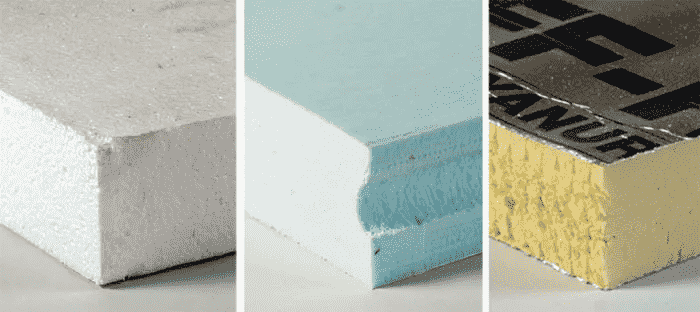

Expanded and extruded polystyrene are both used as insulation in building panels. They range in size from 50 to 152 cm and have similar performance. With these panels, energy loss inside the building can be prevented.

Energy conservation inside the building unit is the most important goal defined for expanded and extruded polystyrene. However, the use of each will be determined according to the different applications. The production method of each of these materials will affect how they are used in the long run.

Production goals

Water absorption

As water penetrates the expanded polystyrene, the insulation function is lost. This use is true in underground and false ceilings. Being aware of the temperature below freezing allows you to use expanded polystyrene properly. Increasing and decreasing the temperature will create a vacuum between the expanded polystyrene beads, and as a result, their insulating properties will be lost. But extruded polystyrene has a closed structure and will not be negatively affected by temperature changes and environmental factors such as water and wind.

XPS

Heat conduction

The thermal conductivity of extruded polystyrene is very low compared to expanded polystyrene. Air transfers heat, and since the molecular structure of extruded polystyrene is more interconnected than that of EPS, extruded polystyrene is perfectly suited for this use.

Compressive strength

The strength of EPS is very low compared to extruded polystyrene. The stronger the foam, the stronger its strength and resistance to pressure.

Conclusion

Expanded polystyrene is made from polystyrene beads, but extruded polystyrene is made from the crystalline beads of this material. Water can destroy the insulating properties of expanded polystyrene, but extruded polystyrene is durable and resistant to environmental factors. For this reason, this type of polystyrene is used in construction.

The molecular structure of extruded polystyrene is closed and therefore has high compressive strength and has advantages over expanded polystyrene.