Plastic polystyrene is used in thermoplastic injection molds. It is a synthetic polymer that is used in the molding of packaging and industrial parts. This material is in the form of foam, plastic, and polystyrene is a non-toxic and odorless material that is used in the packaging industry as well as automation. Polystyrene is produced in two types of General Purpose (GPPS) and High Impact (HIPS) polystyrene, which is used in the manufacture of various car parts and electrical appliances, toys, and plastic packaging containers. Polystyrene is used in the packaging industry in many cases and has many advantages.

polystyrene in Packaging

Properties of polystyrene in the plastics industry

- Resistant to bacterial growth

- Resistant to moisture

- Style

- Suitable for insulation

- Durable

- Recyclable

This chemical is used for different uses and purposes. Pulleys, gears, and rebars are other products that are made by combining this material with other raw materials.

Properties of polystyrene in the plastics industry

Polystyrene is a common raw material used in many industries. This raw material is easily formed and is necessary for making disposable food containers in different shapes and dimensions.

Physical properties of polystyrene in the plastics industry

This chemical is melted at a temperature of -30.6 ° C and the boiling point of this substance is 145 ° C. A temperature of 20 degrees Celsius will cause the material to stick. It has a tensile strength of 700 pounds per square inch and can withstand blows of 8 pounds per foot. Its hardness and endurance is R75 and its flexural modulus is 12,000 pounds per foot. The smell of polystyrene never has a pungent odor. 0.24 g / l is the solubility of polystyrene. The vapor pressure of polystyrene is 5 mm Hg and the refractive index of this material is 1.5469.

Polystyrene is a flammable substance that is harmful to human health and in many cases is a substance that stimulates natural tissues.

Uses of polystyrene in the plastics industry

Physical properties of polystyrene

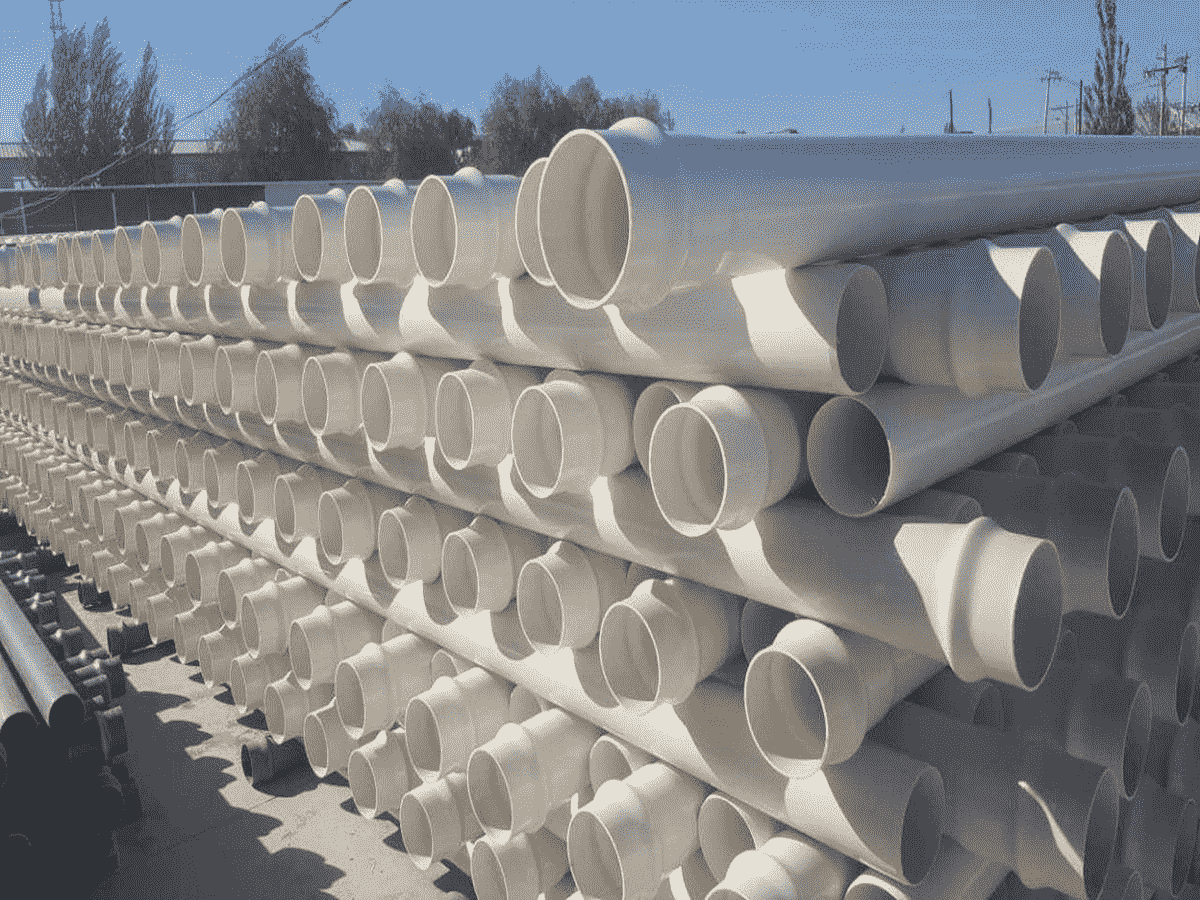

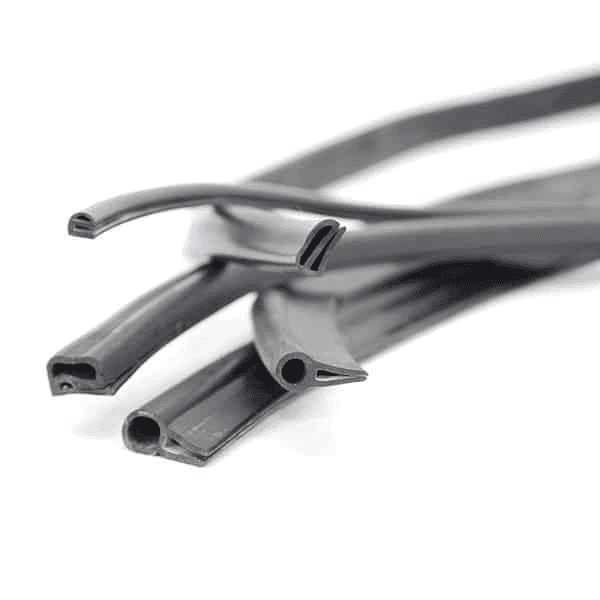

This chemical is used to produce rubber in refrigerators, medical equipment, small appliances, and suitcases. Various types of plastic pipes in the water and sewage industry or other industries, auto parts, and 3D printing are other uses of this chemical. Various car parts, food packaging containers, and optical fiber are also produced with polystyrene.

Many types of sheets and films of the photography industry and other industries are prepared with this chemical. This material is resistant to moisture, various acids, and bases and can be formed more easily. UV resistance, fragility, and high-temperature tolerance are other features of this chemical.

This chemical is used to make tool panels, door panels, child seats, electrical appliances such as televisions, computers, food packaging containers, and the building industry, test tubes and medical equipment, CD / DVD boxes, and packaging containers.

Making synthetic rubber

Use of polystyrene in wires

With this chemical, styrene-butadiene rubber (SBR) and acrylonitrile and butadiene styrene (ABS) rubber can be designed and produced.

SBR rubber is produced by copolymerization of butadiene and styrene. This rubber is resistant to abrasion and cracking.

Butadiene rubber is strong and has good insulating properties and it is easily combined with other materials and is very resistant to abrasion and corrosion. It has a good size, has the necessary stability, and is a bright and shiny material. Sunlight and high temperatures can damage this material.

Rubber sheets

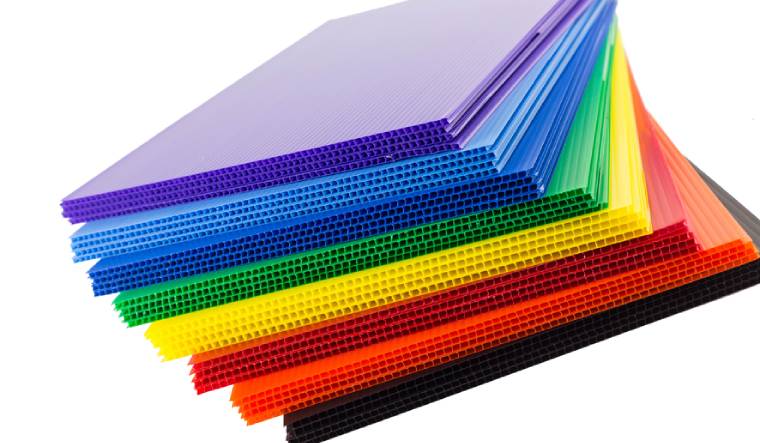

Use of polystyrene in sheets

Many rubber sheets are made with this chemical. Models, replicas, and monitors are other products that are designed and produced with this material. These sheets are cheap and can be used in many cases.

Polystyrene foam

This product is one of the other uses of this chemical. This product is mostly used as building insulation and prevents energy loss inside the building.

Expanded polystyrene (EPS)

This type of polystyrene is strong and white and is used to make rubber in refrigerators, insulation, and in the packaging industry. This material is simple and cheap and always retains its properties. They are easily recycled; Therefore, they do not cause environmental pollution.

Conclusion

The applications of polystyrene in the plastics industry are very important. Various products are designed and produced with this material. With this material, different types of tires can be used in home appliances or everyday life. Polystyrene is a strong and durable material and is highly resistant to corrosion, abrasion, and tearing. The tires made with this material are durable and do not break.