What do you know about polystyrene plastic sheet types? Polystyrene is a chemical that is made from a combination of several different chemicals. This material can be in solid or foam forms. It is chemical, transparent, strong, and somewhat brittle. In all countries, this substance is used in various industries. The chemical is solid at normal temperature. It is heated to 100 ° C and liquefied and re-frozen at a cool temperature. With this method, extruded polystyrene can be prepared, extruded polystyrene can be prepared in different molds.

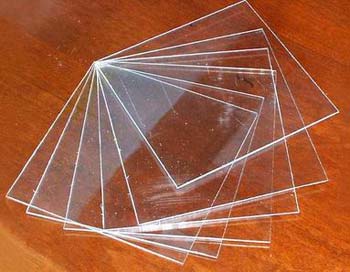

Transparent polystyrene plastic sheet

The material of this sheet is transparent and cost-effective and compared to glass, it is lighter and stronger, and it is easy to transport. It can be easily cut and perforated.

Transparent polystyrene sheet

It can be used for mobile glass protectors, bank glass protectors, clear window panes, oil, and food spread screens when cooking in the kitchen, photo frame, greenhouse glass, garden shed, flower glass protector, protector For food in restaurants, flower and plant protectors in winter.

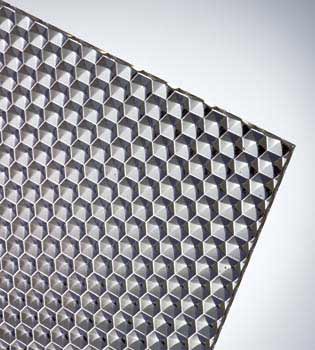

Prismatic polystyrene plastic plate

Prismatic polystyrene plastic plate

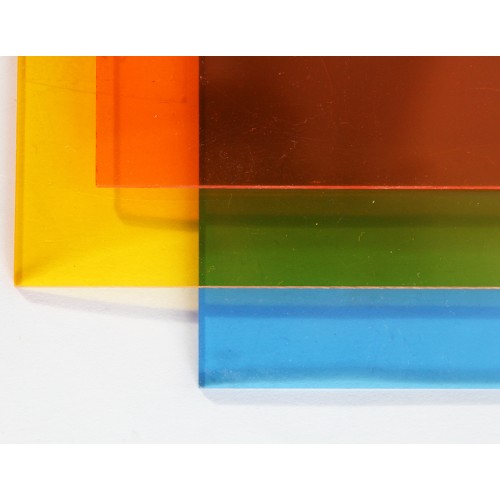

In addition to transparency, this chemical is designed and produced in other designs and colors. The applications of this type of polystyrene plastic sheet are wide and numerous. This sheet is used to scatter light and false ceilings. Natural light can be diffused in different spaces with this sheet.

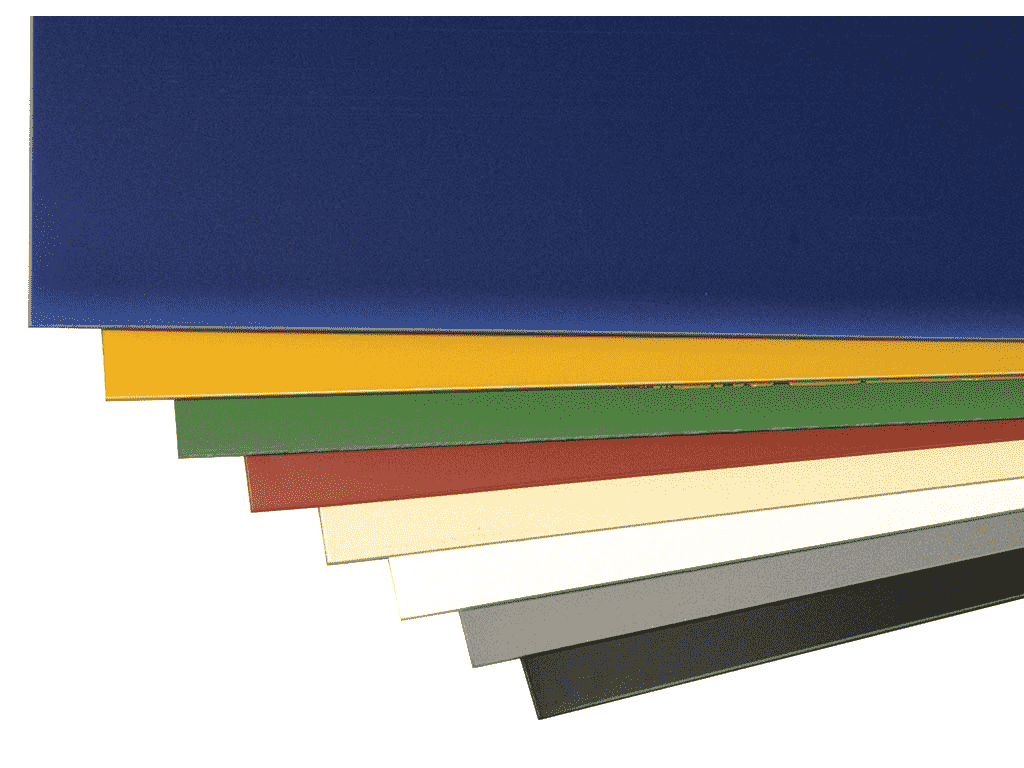

High Impact Polystyrene (HIPS)

High Impact Polystyrene Sheet

This type of chemical is prepared in different dimensions, colors, and designs in two types of opaque and transparent. At the request of the customer, these pages can be customized. This chemical is used to prepare and manufacture vacuums, 3D printing, counters, card readers, labels, and billboards.

Special features of High Impact Polystyrene Sheet (HIPS)

- Ability to connect and weld with other plastic raw materials

- Resistant

- Durable

- Lightweight

- Operating temperature between -50 to 80 degrees Celsius

Different uses

- Chemical processes and storage tanks

- Semiconductor processing equipment

- Building materials of chemical processing industries

- Plating of tanks and shelves

- Kitchen food chopping boards

- Electronic printed circuits

- Prostheses and orthopedic prosthetic parts

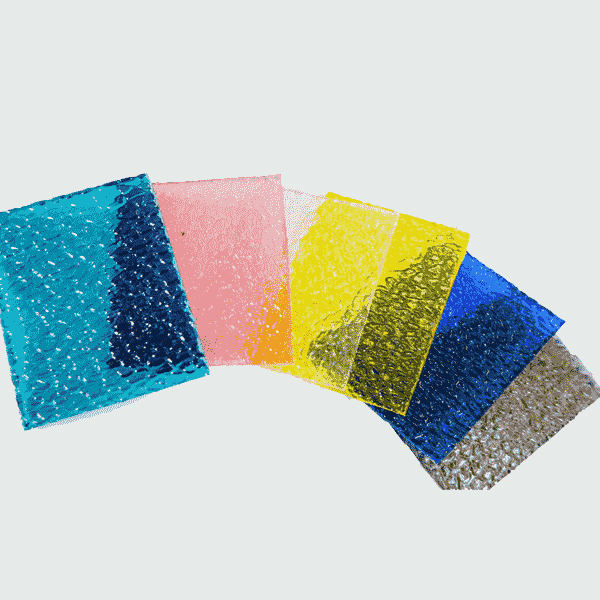

GPPS bulge sheet

GPPS bulge sheets

This sheet is made with patterned rollers. This polystyrene plastic sheet is lightweight and its dimensions are fixed. It is easy to paint, has excellent electrical properties, is easy to process, and absorbs very little water. This sheet can be used in humid environments and retains its properties in such environments. Three-dimensional, layered and stained glass can be made with this sheet. Fragility is a negative feature of this sheet. Compared to High Impact Polystyrene (HIPS), it has less resistance and is severely damaged. It is also vulnerable to ultraviolet light.

GPPS embossed sheet is used in sliding bathroom doors, lamp and lampshade protectors, frosted interior glass, office supplies, laminates, interior decoration raw materials, daily necessities accessories, toy protectors, bathroom interior accessories.

This raw material is strong and easily recycled and transparent. It is very resistant to other chemicals and high heat has no effect on it and absorbs very little water.

GPPS matte sheet

GPPS matte sheets

Light passes through this sheet; So with this sheet, you can create a shadow. It is a lightweight, fixed size, easy to paint, and absorbs very little water.

High Impact Polystyrene Sheet (HIPS)

This sheet is impact-resistant and non-toxic and environmentally friendly. It is used in the food and packaging industries. This polystyrene plastic sheet is used to make insulation for air conditioners and refrigerators, amusement park equipment, movie and theater decorations, sports equipment, and water recreation. Polystyrene can be laminated and used in the construction industry.

Polystyrene in the construction industry

Polystyrene is also used in this industry. polystyrene plastic sheet can act as sound and energy insulation and prevent energy loss inside the building. In addition, it is a barrier to noise pollution. With this material, many spaces can be created artificially in any environment.

Conclusion

Polystyrene is a chemical made from a combination of several raw materials with different properties. It is divided into High Impact Polystyrene (HIPS) and General Purpose Polystyrene (GPPS). The applications of each of these raw materials are different from the others.

polystyrene plastic sheet is used in many cases as a shield. High Impact Polystyrene (HIPS) is used in the electronics, chemical, medical and pharmaceutical industries. GPPS transparent and matte embossed sheet is used in home decoration and making many office supplies.