Polystyrene roof blocks are designed and produced with a width of 50 to 70 cm, a length of 1 to 2 meters, and a height of 10 to 30 cm. With a density of 1 to 2 KG/M3, it is one of the most compact products that can be used for building roofs.

Learn more about polystyrene roof blocks

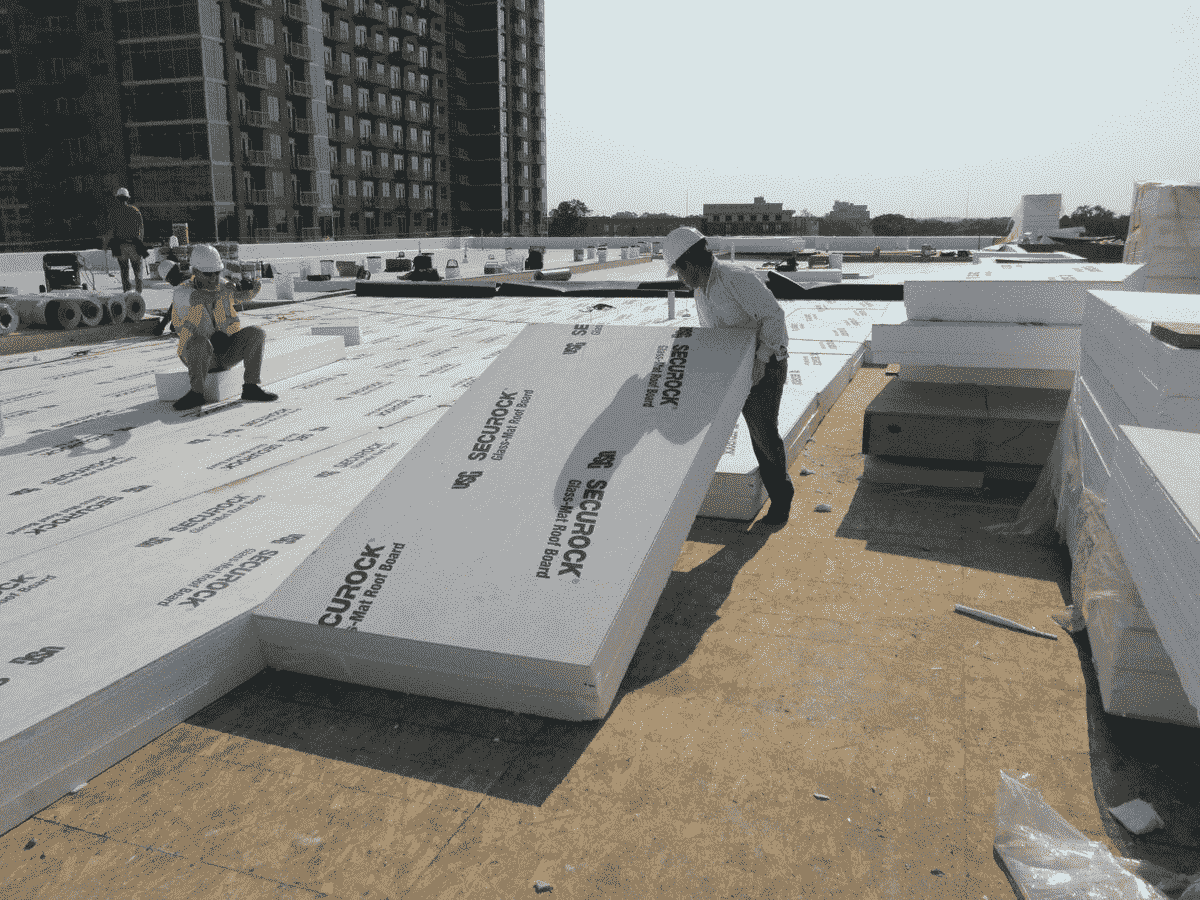

Polystyrene roof blocks are widely used in construction. They can be easily used on-site and do not require special tools. Using these materials, cement slurry can be eliminated and they are considered the best energy insulators. They are light and easy to install.

Today, polystyrene roof blocks are widely used in construction. The use of these materials is cost-effective, recyclable, and has no impact on the environment. These roof blocks have been used in construction for more than 45 years.

Advantages of polystyrene roof blocks

Advantages of the polystyrene roof block

Polystyrene roof block is the best alternative to 120 kg roof tiles and this can save a lot on the foundation and structure of the building. The width of the polystyrene block is suitable; For this reason, it can be used instead of beams.

The Building Fuel Optimization Organization recommends the use of polystyrene blocks. They can be easily moved to the upper floors of the building. The presence of polystyrene blocks reduces the possibility of falling building materials. It is the best insulation against heat, cold, and sound and prevents up to 70% of energy loss.

Polystyrene roof block reduces the weight of the structure. The use of concrete is saved by 30% and steel by 25%. It is resistant to fire and with the use of some building materials such as cement and plaster will be halved.

This increases the useful life of the building and minimizes the need to mold concrete formwork. Resistance to insect infiltration is another advantage of polystyrene roof blocks.

Benefits of using polystyrene roof block

- The best energy and sound insulation

- Reducing energy consumption

- Save on building costs

- Cheap and affordable compared to concrete and cement blocks

- Easy to install, use, maintain

- Cheap

- Less use of concrete

- Durable

- Environmentally friendly

- recyclable

- Fire resistant

- Water and moisture resistant

- Lightweight

- Less use of concrete columns

- Resistant to vibration, wear, corrosion, breakdown

- Free of carbon compounds

- Healthy for the ozone layer

Applications of polystyrene roof block

The best alternative to other roofing materials

The use of cement and concrete is often not cost-effective in construction. Due to the lightweight polystyrene roof blocks, they can be easily used. These materials are also resistant to lateral pressures. These materials can save a considerable amount of money.

Applications of the polystyrene roof block

Uses of these blocks are insulation of concrete roofs, metal, and steel floors, wood, and roof garden, green roof gardens, attics and silos, and depots, as well as for isogum, single-layer membrane (TPO, EPDM, PVC), prefabricated roof and reverse systems.

Ballast systems, PARS adhesive roof system, AARS adhesive roof system, and mechanical roof system (MARS) are other applications of these new and cost-effective materials.

Polystyrene roof blocks are a very important part of any building

Since these materials are used in construction, it can be claimed that they are an integral part of the construction. These blocks prevent energy loss. In addition to the roof, they can also be used on the floor of the building.

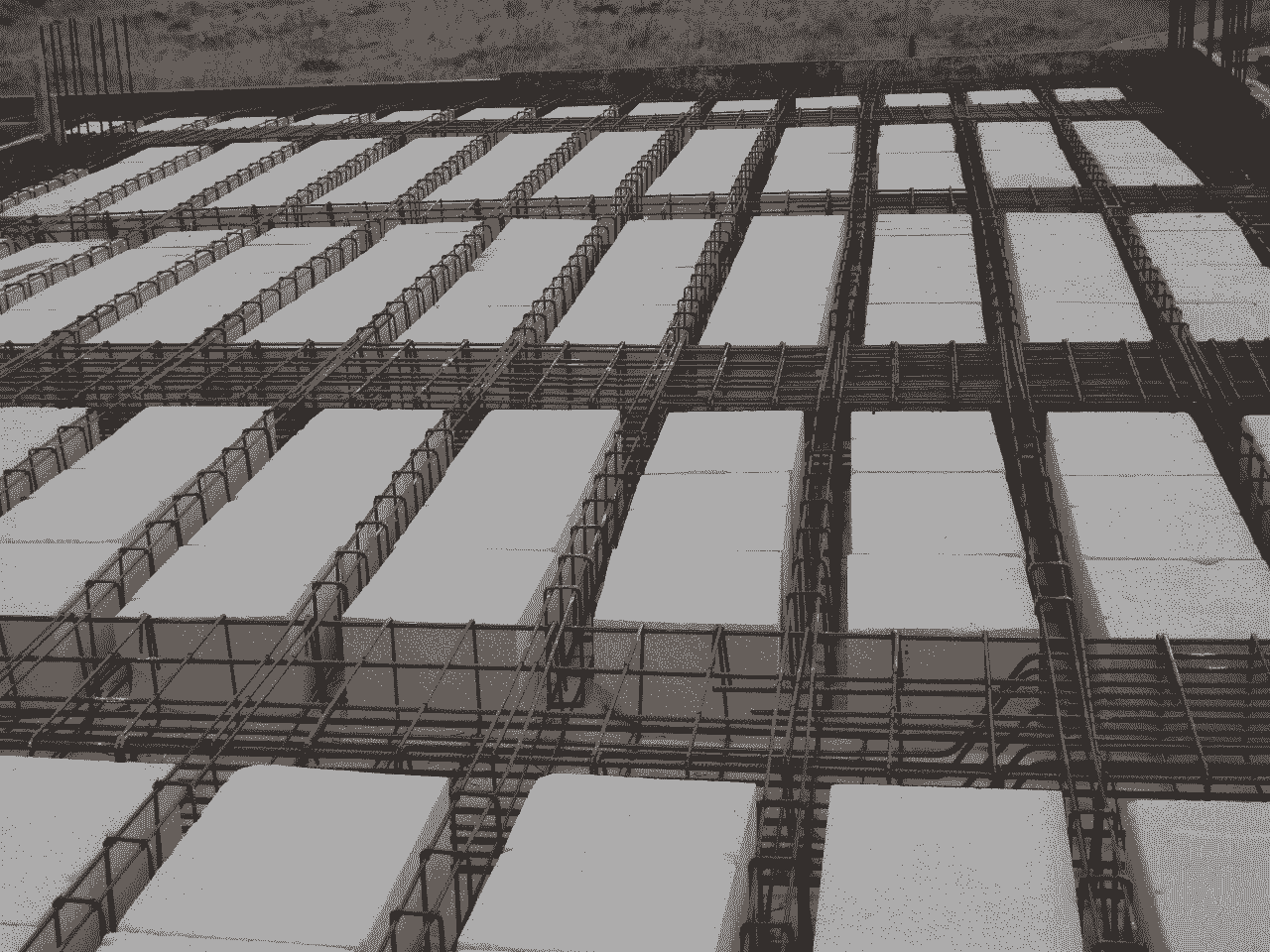

These materials are piled up and formed by pouring concrete on them. Doing so increases the stability of the building. Before doing so, the rebars are dipped into the blocks. As ribbed and sometimes flat rebars are planted in concrete blocks to strengthen the building structure.

Conclusion

Polystyrene roof blocks are one of the newest building materials that have many benefits and advantages. These materials are standard insulation against sound and energy. When using these materials, less cement and concrete can be used.

Recoverability makes it possible to reuse waste blocks. These materials are environmentally friendly and free of harmful carbon compounds. They are also not harmful to the ozone layer. Moheb Baspar Company provides and supplies these materials at a reasonable price.