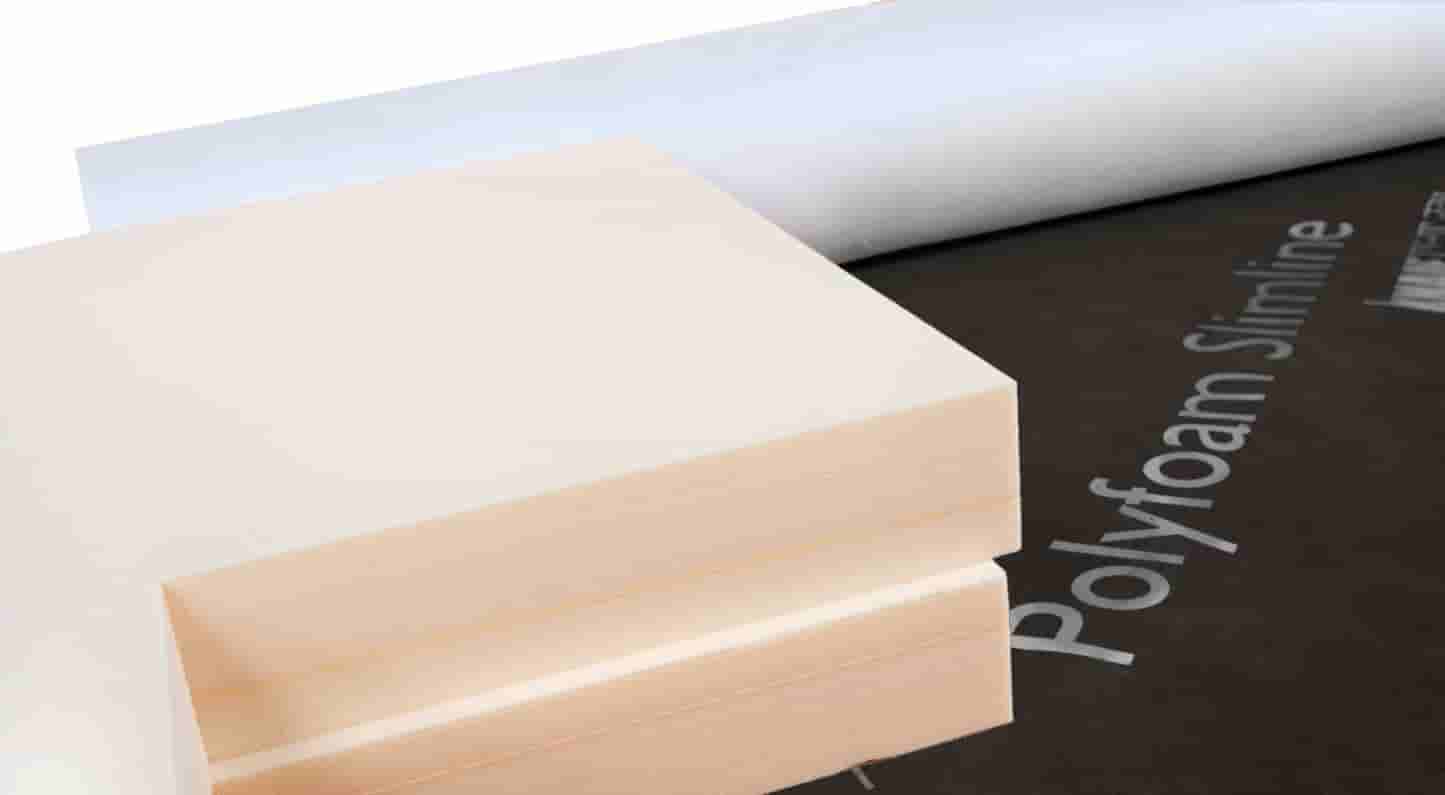

Extruded polystyrene is a type of thermoplastic material. Its cellular structure is closed and it is strong compared to other polystyrenes and has a high performance. It is also more expensive than EPS.

XPS

The nature of extruded polystyrene

Polystyrene is a fragrant synthetic polymer made from styrene monomer and derived from ethylene and benzene. This material can be foam or solid. Polystyrene is transparent and colorless, and with this material, foam insulation or board nuts can be designed.

95% to 98% of these materials are made of air and are the best thermal insulators that can be used in most cases for concrete insulation and structural insulation panel systems. The nature of extruded polystyrene is the same as other polystyrenes, but EPS are small grains made with molten material.

The density range of extruded polystyrene is between 28 and 45 kg / m3. Extruded polystyrene is produced like polystyrene and it can be said that crude oil is present in its material base. The process of producing extruded polystyrene is different from expanded polystyrene.

Applications of extruded polystyrene

Extruded polystyrene has a wide variety of applications. It can be used for building insulation, building floors, and concrete floors. This material can be used in hand models, especially in architecture. Water penetrates the extruded polystyrene; So this is never a barrier to water evaporation.

Applications of extruded polystyrene

Thermal conductivity of extruded polystyrene

Extruded polystyrene can transfer heat in proportion to its thickness, which is typically measured in watts. The lower the heat transfer coefficient of materials, the more heat and heat they can transfer.

The thermal conductivity of extruded polystyrene is between 0.025 and 0.040 watts per meter. Extruded polystyrene easily transfers heat and prevents large-scale convection.

Extruded polystyrene foam board is the best material you can refer to for insulation of ceilings, walls, attics, foundations, and basements. This material can be effective in saving energy at higher temperatures.

The higher the density of the material, the greater the heat transfer capacity. There are gases in XPS that shrink and disappear as they exit.

How to produce XPS?

Its production process is like polystyrene and resin grains are used during its production. This material is heated and melted at higher temperatures. This material is used as an additive in the melt mixture. XPS is used in the paint industry.

This material is painted in different colors to be more specific. With pressure and heat, you can control how this product is produced. The plastic mixture is pressed out of the mold and cooled and expanded at room temperature, and finally cut to the desired size.

High Impact Polystyrene (HIPS)

High Impact Polystyrene is a type of polystyrene that becomes resistant by adding rubber. It has a very high resistance compared to ordinary polystyrene and softens and flexes as soon as it heats up and solidifies and hardens again after cooling.

This material can be used in the production of various parts. This material is cost-effective to make and can be used for impact resistance and machining.

Sale of phthalic anhydride (PA)

Phthalic anhydride or PA is an aromatic carboxylic acid in the form of a white powder. Occasionally it appears as a clear, colorless liquid and has a very pungent odor. You can get this material from the sales department of Moheb Baspar Company.

Phthalic anhydride

Sales of Dioctyl Phthalate (DOP)

DOP is a colorless oil that smells very subtle. It is used in the PVC industry and other PVC products can be used with it. This material is sold in Moheb Baspar Trading Company.

Buy General Purpose Polystyrene (GPPS)

You can buy this General Purpose polystyrene from Moheb Baspar Trading Company. It should be noted that this is used in the petrochemical industry.

Conclusion

Extruded polystyrene is stronger than polystyrene. 95 to 98 of it is made up of air, which gets smaller as it comes out and eventually disappears. It is used for building insulation, building floors, and concrete floors.

XPS foam board is also used to insulate roofs, walls, attics, foundations, and basements. During production, the resistance of this material increases by adding resin grains.