Polyurethane sandwich panels were used in construction. Polystyrene sandwich panels are a new phenomenon used in construction. This is a good replacement for this structure.

Differences between polyurethane and polystyrene

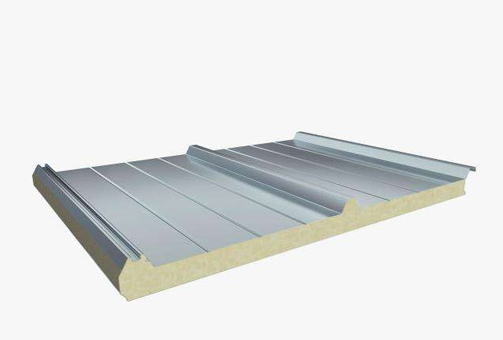

Polyurethane is one of the best insulators in the world and it is used in the manufacture of air conditioners, refrigerators, and freezers. Many home appliances are designed and made with polyurethane.

How to produce polyurethane and polystyrene

The production method of these two distinguishes between them. These are used as a material on both sides of the foam. Polyurethane is used in the industry as an adhesive. Some products are even designed and manufactured with three layers of polyurethane.

Polystyrene sandwich panels are used on both sides of the parquet. Polyurethane is also used for the same purpose. The size of the parquet matches the polystyrene sandwich panel. After gluing the sandwich panel, the polystyrene is subjected to mechanical pressure to dry the glue.

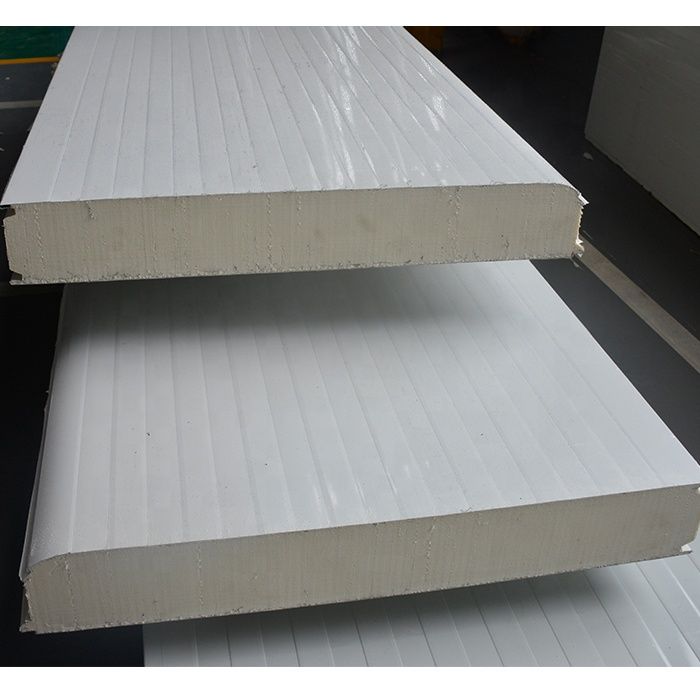

Polystyrene sandwich panels

Moisture feature of polyurethane and polystyrene sandwich panels

Moisture resistance is one of the prominent features of polystyrene sandwich panels. A polyurethane sandwich panel is also equipped with this feature. Moisture resistance in polystyrene sandwich panels is 2 to 5% and this amount is 1.2 in polyurethane sandwich panels. Therefore, it turns out that the performance of urethane sandwich panels will be better than polystyrene.

Fireproof feature of polyurethane and polystyrene sandwich panels

The chemical polyurethane does not burn normally, it can even act as a fire extinguisher. This material catches fire at a temperature of 1000 degrees Celsius. Polystyrene is in good condition and softens at 180 ° C and melts at 240 ° C. Polyurethane has advantages in this property over polystyrene.

Compressibility of polystyrene and polyurethane sandwich panels

Density is one of the advantages of the product. The density of polyurethane is 2.2 pounds and polyurethane is 1, which again puts polyurethane in a better position.

Chemical resistance properties of polyurethane and polystyrene sandwich panels

Polyurethane is resistant to chemicals and polystyrene is neutral to petroleum products. The properties of both substances are similar in many ways.

Moisture-proof polyurethane sandwich panel

Advantages of polyurethane sandwich panels

- Appearance charm

- Proper insulation

- The lowest heat coefficient

- Durable

- Ability to create various profiles

- UV resistant

Polystyrene sandwich panels should not exceed 7 meters, and if more panels need to be installed, short panels can be attached to the expanded ones.

Advantages of polyurethane sandwich panels over polystyrene

Polystyrene sandwich panels are stronger than polystyrene and these panels are used in buildings and car seats. These panels make the structure more valuable.

Polyurethane is an expensive material that does not increase the financial value of door panels. These panels are thicker than panels that do not contain polyurethane. By adding this material, part of the panel looks wavy.

Polystyrene sandwich

Polystyrene is made from a combination of several chemicals. It is a brittle white substance and is widely used in transportation. This material is used inside the front panels of the structure. This material does not deform.

Polystyrene does not fit completely inside the panel. It should be noted that parts of the structure remain empty. Stylish sandwich suspended ceilings have disadvantages compared to polyurethane and are not suitable for use on ceilings.

The advantages of polyurethane for the use of sandwich panels are known, and with such a sandwich panel, suitable insulation can be provided.

Comparison of polyurethane and polystyrene sandwich panels

Polyurethane paint is yellow and occupies more volume and prevents energy loss. The density of this material is high and it does not catch fire by itself. It does not melt or deform at any temperature. It is resistant to moisture and the penetration of water and all chemicals.

The mechanical, chemical, and adhesive properties of this material are excellent and increase the resistance of the structure to environmental factors. It is inexpensive to install and does not require additional costs for wood panels and wiring. This material can be used in all parts of the structure or building, such as doors, windows, the underlayment of panels, roofs.

Polystyrene is white and does not cover all parts of the panel. It is vulnerable to moisture and catches fire easily and is not suitable for use at temperatures above 180 degrees. Water vapor and base oil solvents, oils, and solvents are vulnerable.

Polystyrene sticks to wooden panels. It cannot be used for doors and windows and is not compatible with electricity. You need to pay for the use of styrene in door panels, windows and ceilings, and building columns.

Conclusion

Polyurethane sandwich panels have many advantages over polystyrene. It covers the entire interior of the panel and prevents energy loss and has excellent mechanical, chemical, and adhesive properties. It also melts and does not deform at any temperature. Polyurethane sandwich panels are water-resistant, chemical resistant, and do not normally catch fire. This material can be used in different parts of the building in doors, windows, ceilings, columns.