Polystyrene is produced by various devices. With polystyrene devices, the product can be produced in the form of grains, granules, sheets, and blocks. Because polystyrene is resistant to environmental factors, it is used in many industries. This material has unique properties. The ineffectiveness of water and bacteria is one of the simplest properties of this chemical raw material. The stability of properties has made this chemical more popular; The specific molecular structure is the most important reason for these properties that should not be ignored.

All kinds of polystyrene devices

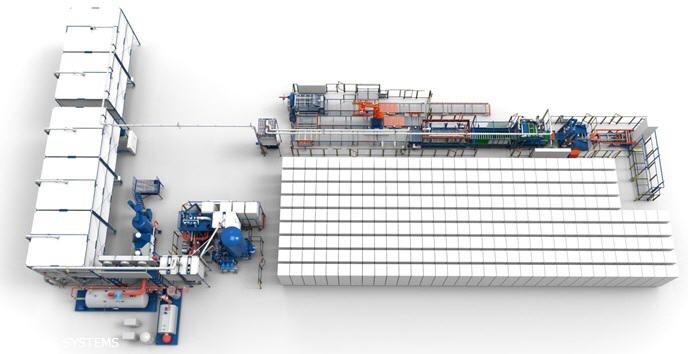

Polystyrene devices are designed in different types and varieties. The ability to produce in bulk is the most important feature of these devices. The maintenance cost of these devices is very low and the factory manager can produce more products at a lower cost.

The most important polystyrene production devices

Polystyrene production machine

With these devices, polystyrene blocks are separated and arranged in pallets. With this device, you can create polystyrene sheets and the ability to save automatically is another feature of the device. With this device, several polystyrene products can be produced simultaneously. Polystyrene devices are updated every year.

You can even specify product cut lines and do just that. Packaging polystyrene products is another feature of the device.

With this device, waste polystyrene can be recycled. It is equipped with steam washing, water washing, and a product compactor. Polystyrene devices have many capabilities.

Depending on the capabilities, different tasks can be performed. Each manufacturer can use these devices for their production goals. The parts of the device can be separated from each other and a different product can be produced from them.

This feature will improve the quality of the final product. The ability to define new product features can be considered one of the features of these devices.

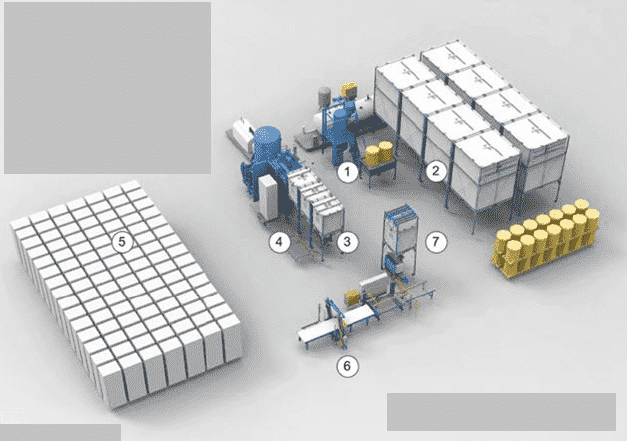

Semi-automatic polystyrene machine

5 or 6 operators work with this device at a time. The ability to create wide polystyrene sheets is another feature of the device. It is even possible to produce several products at the same time.

Semi-automatic polystyrene machine

The vacuum system is included in this machine and the possibility of professional cutting adds to the attractiveness of the machine. Recycling of waste polystyrene and the possibility of washing the product with steam and water are other features of the device. Even the ability to compact the product is another feature of the device.

VIRO production machine

Other polystyrene devices include the Viro device, in which 5 or 6 operators operate simultaneously at a time. The possibility of producing wide product pages is another feature of the device.

Several types of polystyrene can be produced simultaneously. Professional cutting of parts and plates is another feature of the machine. The possibility of recycling waste polystyrene adds to the attractiveness of the device. Steam and water washing is one of the most important features of the machine. The possibility of compressing polystyrene will cause mass production of the product. All devices are manufactured according to European standards.

VIRO production machine

This is the smallest polystyrene device and can be used to mass-produce the product. The production capacity of this device is 50 cubic meters. This fully automatic device will make you more profitable. With this device, high impact polystyrene (HIPS) and general purpose polystyrene (GPPS) can also be produced.

Waste polystyrene recycling machine

With this device, 15-20 kg / m3 of general purpose polystyrene and 28-45 kg / m3 of extruded polystyrene can be recycled.

Waste polystyrene recycling machine

Polystyrene is collected and compacted and eventually converted back into polystyrene. The amount collected is required to reach 200 kg / m3.

Extruded polystyrene device

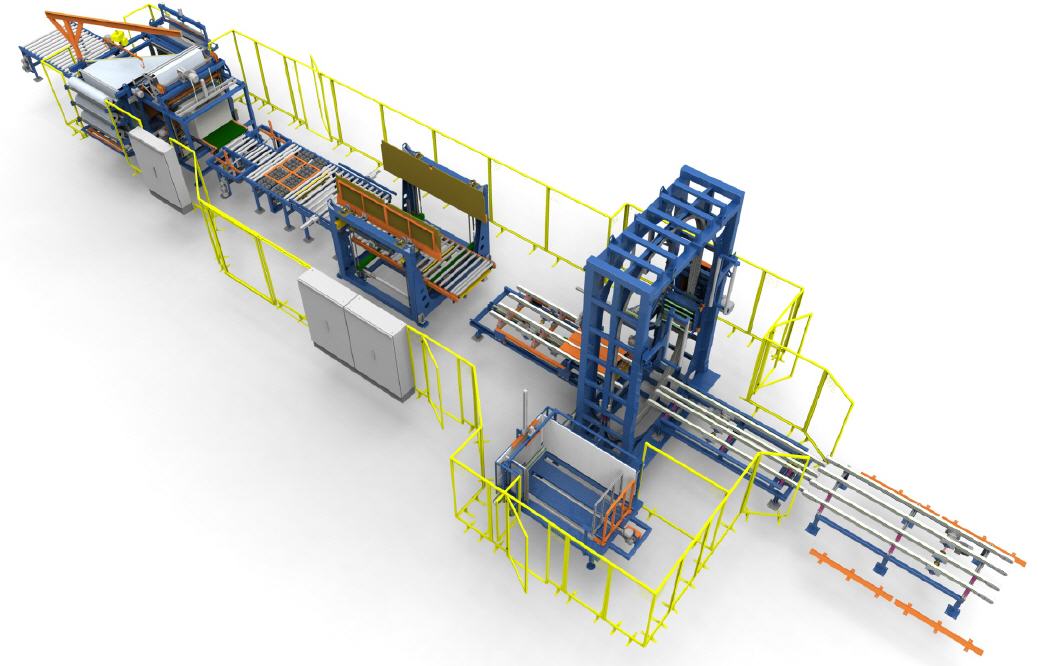

Production machine of 400 to 2000 kg per hour

Extruded polystyrene can also be produced with VIRO machines, and this product is like hard foam. The features of the machine include product packaging, palletizing, moving, cutting the produced product.

Extruded polystyrene device

Conclusion

Polystyrene devices are different and the possibilities of polystyrene devices are many. The possibility of automatic, semi-automatic packaging, washing the product with steam and water, and compacting and cutting the product into parts and plates in different sizes, are other attractive features of these devices. Such features are included in extruded polystyrene devices.