Principles of handling and storing phthalic anhydride

What do you know about the principles of handling and storing phthalic anhydride? As you know, phthalic anhydride is a white organic compound. It has a relatively pungent odor that can be dissolved in water, alcohol, and other organic solvents. This material is used in many applications such as insecticides and plasticizers, dyes, and phthaleins. Join us to learn how to move and store phthalic anhydride.

Guide to the storing phthalic anhydride

Identification of phthalic anhydride

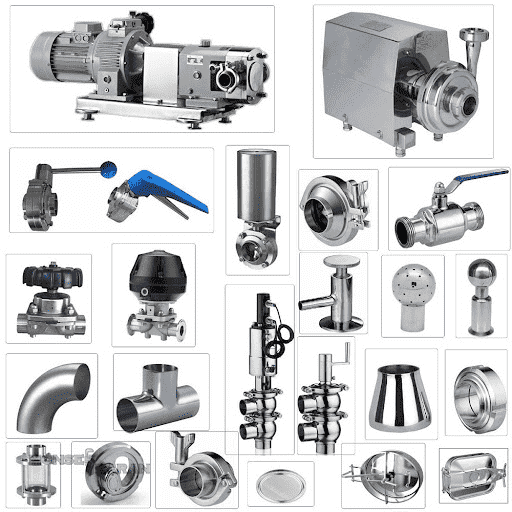

When handling and storing phthalic anhydride, make sure that this chemical must be carried in tightly sealed containers. Phthalic anhydride should be stored in a cool, dry place away from sunlight. Another thing to keep in mind when storing this material is not to place containers containing phthalic anhydride in the presence of alcohols, strong acids, bases, and amines. When moving this material, safety methods that are based on appropriate hygienic standards should be used.

Another important factor in the handling and storing phthalic anhydride is the implementation of related engineering controls and proper exhaust ventilation. If phthalic anhydride particles are inhaled by people, it is possible to irritate the respiratory system and cause asthma and allergic symptoms.

Phthalic anhydride can severely irritate and affect the skin. These symptoms are more common on wet skin and can lead to skin eczema. This material can affect the eye and cause it to irritate. In case of contact with the eye, it can also damage the cornea and conjunctiva. Therefore, it is necessary to be careful when transporting and maintaining it and observe the use of personal protective equipment.

Animal studies suggest that if phthalic anhydride is exposed to intense steam, it is possible for lung cells to become irritated, condensed, and severely damaged. So far, no study has been reported on the effects of this substance on carcinogenesis and reproduction.

Identification of phthalic anhydride

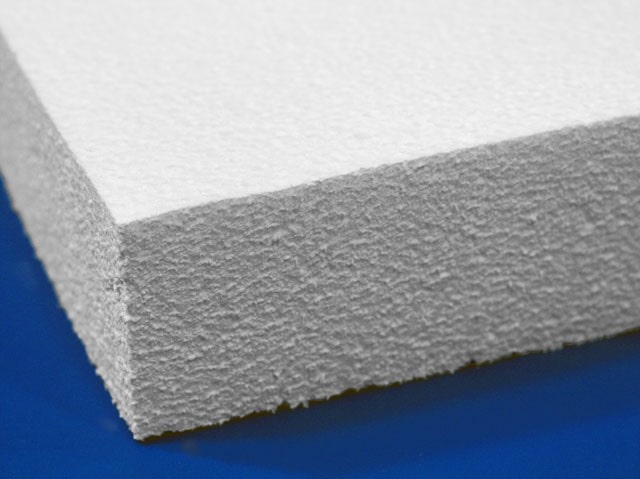

One of the most important things during the handling and storing phthalic anhydride is the identification and detection of this substance. This material is a type of carboxylic aromatic acid. It is available in two forms of colorless liquid and layered powder with a distinct and relatively pungent odor that is quickly detected. In Iran, this substance is usually known as phthalic anhydride and due to its high volume of production and consumption in the world, it is not difficult to distinguish it by comparing.

Phthalic anhydride is known as a colorless toxic solution that combines with alcohol and carbon disulfide. It dissolves slightly in hot water and is converted to hydrolyzed phthalic acid. This acid is considered the first dicarboxylic anhydride acid with a capacity that has a high commercial consumption. This acid can be measured with acetic acid in terms of importance.

Phthalic anhydride is plated, colorless, acicular, and colorless in a monoclinic crystalline form or a rhombic position. The most important PA derivatives are paints, emollients, and polyester resins. It is synthesized for the first time in Germany in the form of oxidation of naphthalene with mercury catalyst in the liquid phase in an acidic environment. Using this method caused the obtained product to lack the desired quality.

The most important applications of phthalic anhydride

The most important applications of phthalic anhydride

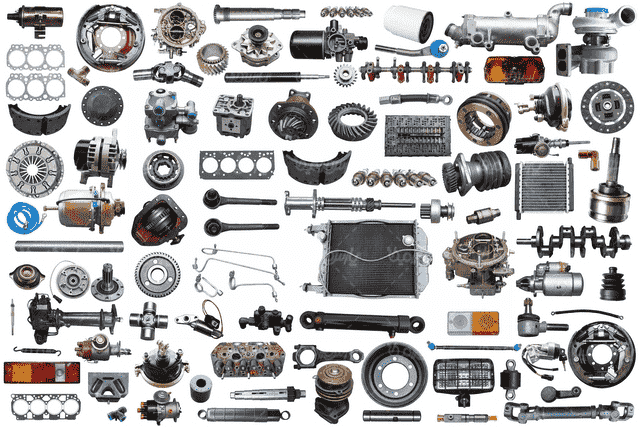

One of the most important applications of phthalic anhydride is in the synthesis of plasticizers. It is commonly used as a chemical intermediate in the manufacture of softeners made of polyvinyl chloride. Another use of this material is the production of polyester resins and is used in part to produce alkyd resins. This material is used in paint and varnish industries; Other examples of its use include the use of polyurethane and insect repellents.

One of the most widespread applications of phthalic anhydride is in the production of unsaturated polyester resins, which often combine with glass fibers to produce fiberglass and reinforced plastics. This material is used to make alkyd resins based on solvent coatings for applications in machinery, architecture, and furniture.