Possibility of transferring hazardous packaging chemicals to food

The transfer of hazardous packaging chemicals to food is one of the unforeseen events that can happen in some cases, but health experts are trying to prevent the transfer of hazardous chemicals into food.

Once a tank is specified for transporting food, it needs to be used for the same use. It should not be used at all to transport other substances, especially hazardous chemicals.

Today, all countries have strict rules for the movement and movement of food and chemicals. Drivers carrying chemicals and food must follow these rules.

Terms of food trucks

- Freeze temperature or proper ventilation

- Use of transportation facilities to transport food

- Use proper methods of handling and transporting food

- Daily cleaning of food trucks

- Communication and coordination between carrier and receiver

Food companies are responsible for the safe and correct transportation of food. Preventing the transfer of hazardous packaging chemicals to food is one of the principles that must be observed.

Separation of hazardous chemicals from food

Separation of hazardous chemicals from food

Hazardous chemicals should not be carried with food. Of course, the truck carrying chemicals is separated from the food truck. Even if you do not have enough space to carry food, it is recommended that you do not place it near chemicals. If you see non-compliance with this law, report the matter to the CEO to avoid further consequences.

Because hazardous chemicals are flammable, they need to be transported in separate tanks. Keep these materials away from sunlight and fire to eliminate the risk of fire in fixed or moving tanks.

General principles of hazardous packaging chemicals

- Put the group chemicals together according to the known chemical reactions

- Due to the incompatibility of acidic chemicals with alkaline

- Separation of chemicals from water tanks

- Separation of reactive chemicals in each situation

- Separation of chemicals from all food groups

- Separation of chemicals from explosives, radioactive and spoilage materials

- Separation of all chemicals from other hazardous materials and products

Safe transport of hazardous chemicals in trucks

Always carry hazardous chemicals properly and by the rules. Place hazardous chemical tanks without shaking, so that they do not come into contact with each other.

To prevent the possibility of hazardous packaging chemicals being transferred to food, wrap aluminum foil over the food and stretch the foil completely. So that there is no seam between the food and the packaging.

List any solid, liquid, or gaseous chemicals and the characteristics of each. This is usually done in commercial companies.

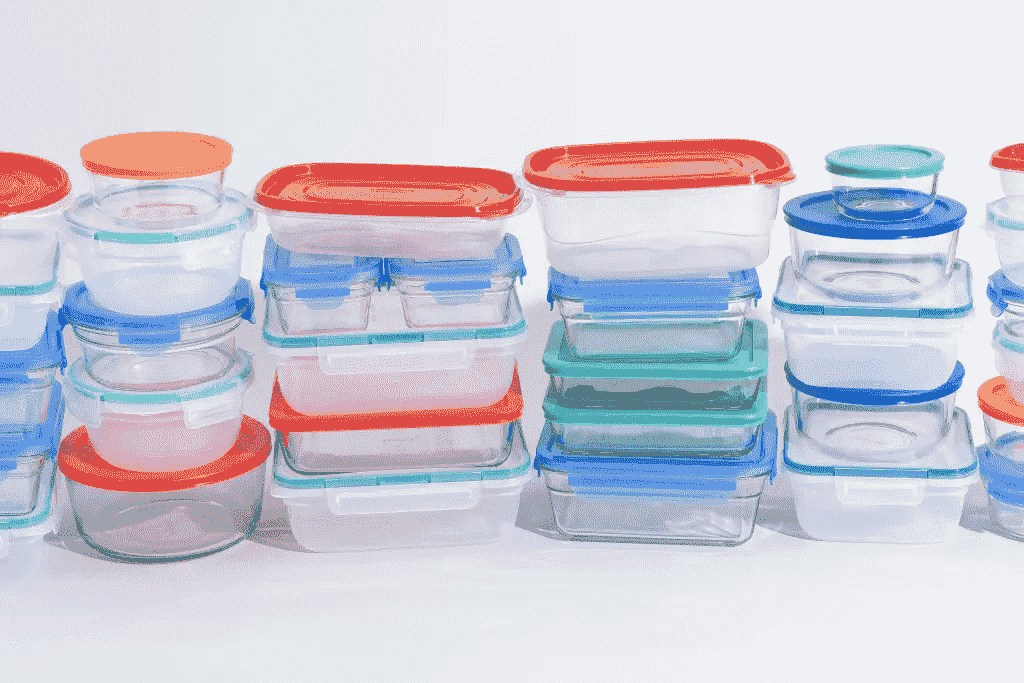

Experts have already warned against the possibility of these substances penetrating food. When silicone sealed containers are exposed to high temperatures, chemicals seep into the food.

Of course, the transfer and penetration of chemicals occur not only during packaging but also during cooking and preparation of raw materials.

Safe transport of hazardous chemicals

Methods to prevent the transfer of hazardous packaging chemicals to food

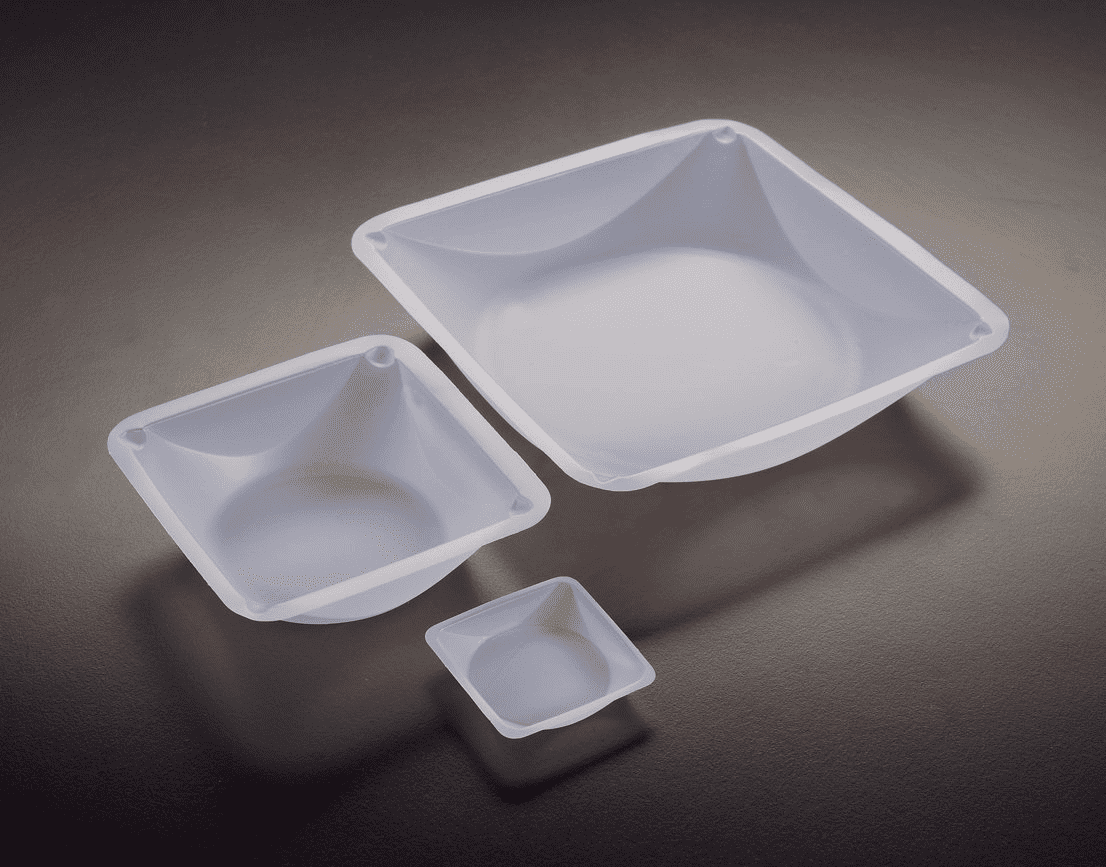

The best way is not to use disposable packaging containers. If you use these products, heat the food in another iron pan and taste.

When you have access to stainless steel plates, cutlery and spoons, it is recommended that you eat with them.

By purchasing High Impact (HIPS) polystyrene from Moheb Baspar Company, you can offer it to buyers and customers. It is recommended that you buy this basic chemical in bulk.

The price of phthalic anhydride (PA) offered by Moheb Baspar Company is reasonable and fair. You can buy it and use it to make industrial lubricants.

The price of dioctyl phthalate (DOP) of other companies is higher than the price offered by Moheb Baspar Company. Knowing this, you can buy this material at a reasonable price in bulk and according to your needs.

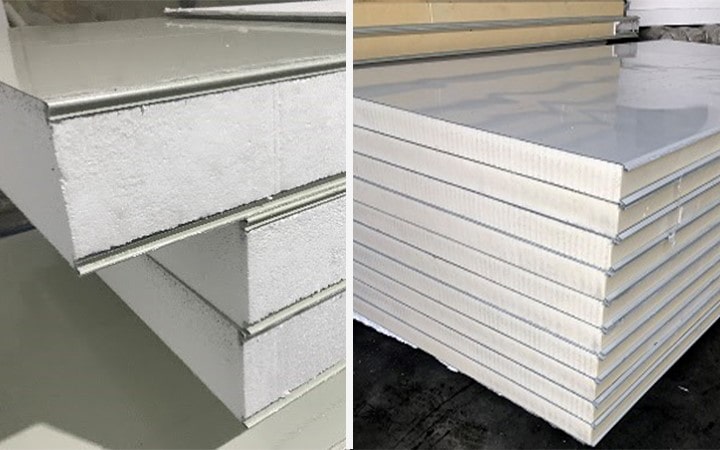

General Purpose (GPPS) polystyrene is sold like extruded polystyrene in good condition. You can buy this chemical raw material at a reasonable price from Moheb Baspar Company.

Conclusion

Hazardous chemicals that are harmful to human health have been used in the manufacture of disposable food containers. To have a healthy life, these dishes can be used less in everyday life.

Alternatively, aluminum foil can be applied to food to prevent the transfer of hazardous packaging chemicals to food. To date, no healthy chemicals have been identified that are not harmful to human health. Therefore, consumers need to be sensitive to their health. It is hoped that the use of these dishes will be minimized and in another plan will be completely removed from people’s lives.