Investigation of applications of polystyrene in different cases

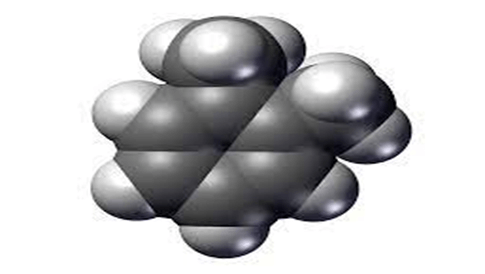

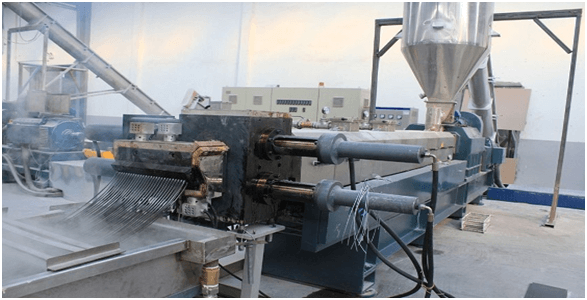

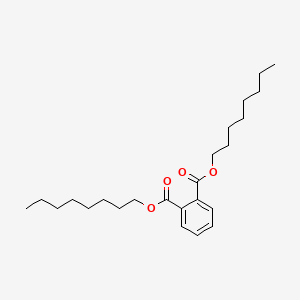

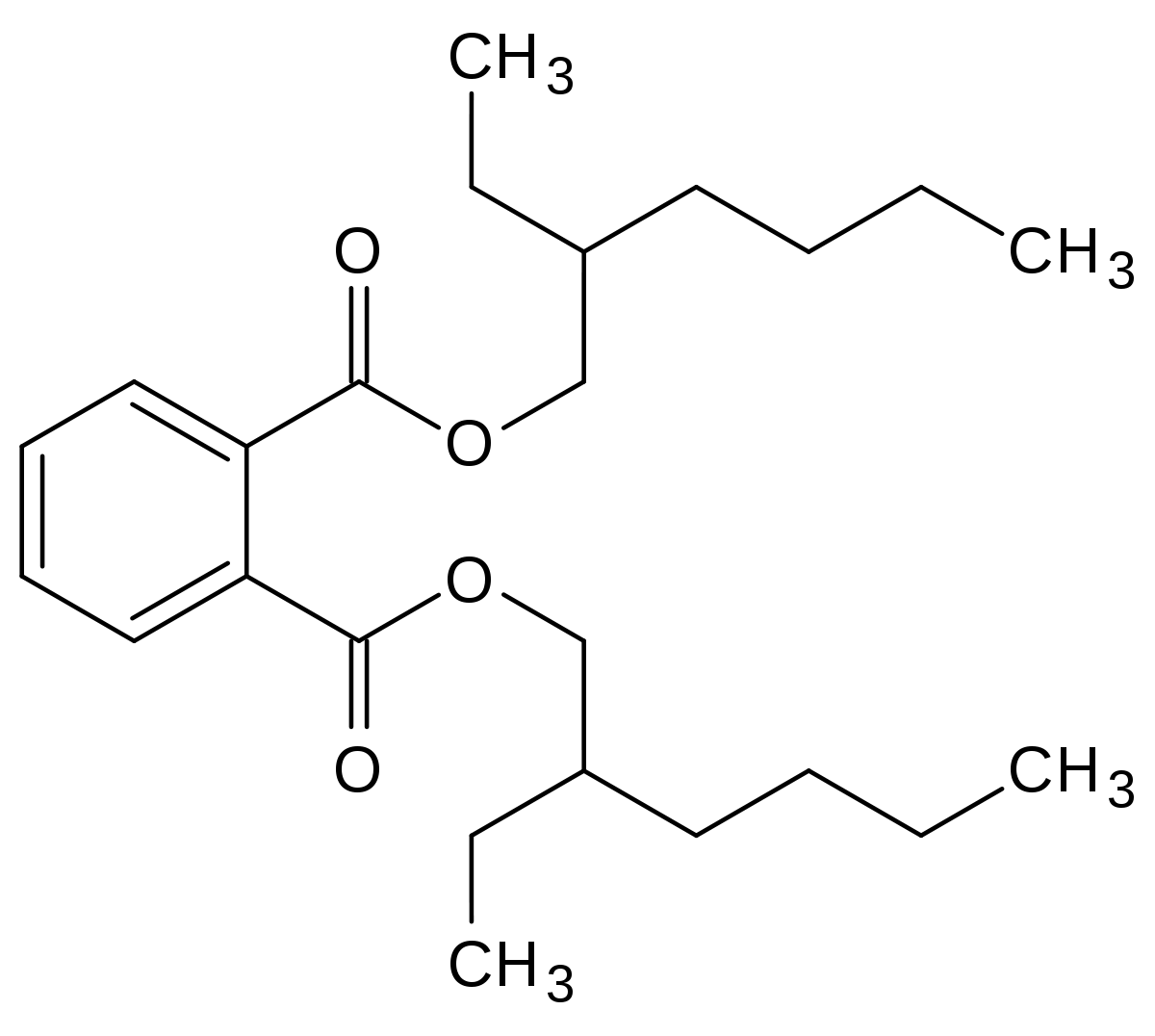

What do you know about the applications of polystyrene? Polystyrene is considered one of the most special chains in the petrochemical industry. This chain is in the category of phenyls and is one of the longest carbon queues in chemicals. Polystyrenes contain the carbon and hydrogen of chemical elements.

The main feature of this material is the integration of the van der Waals bond in the shortest possible time in the polymer chain. The longer the carbon chain, the higher the tensile strength. This has made polystyrene more efficient.

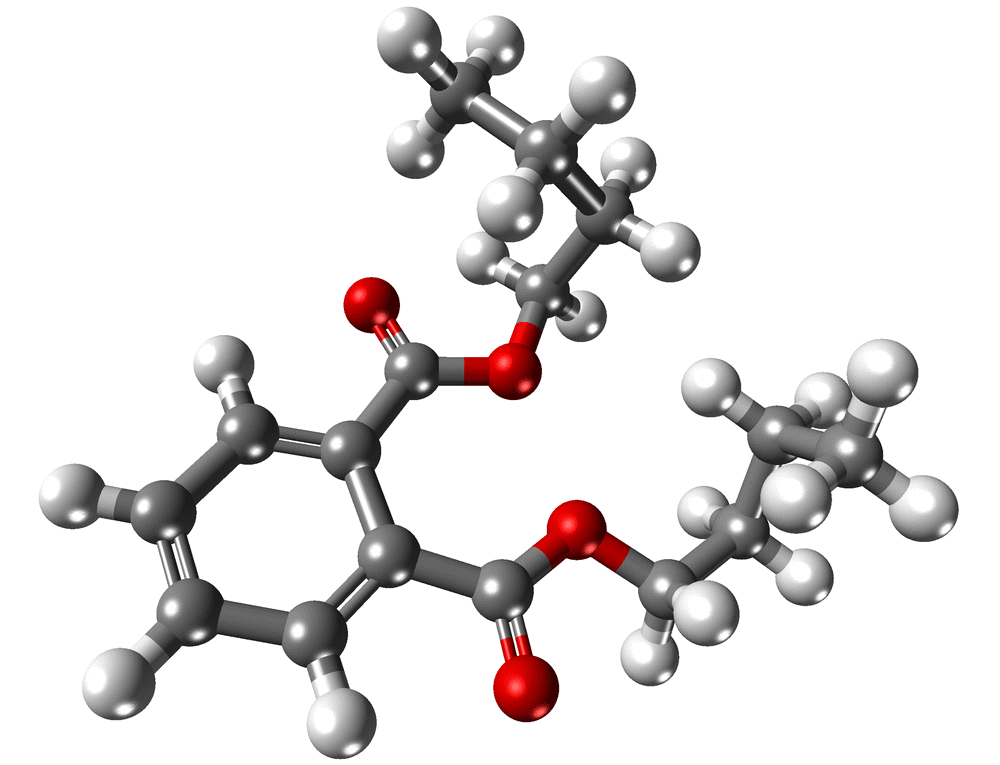

Ionolite

Familiarity with the applications of polystyrene

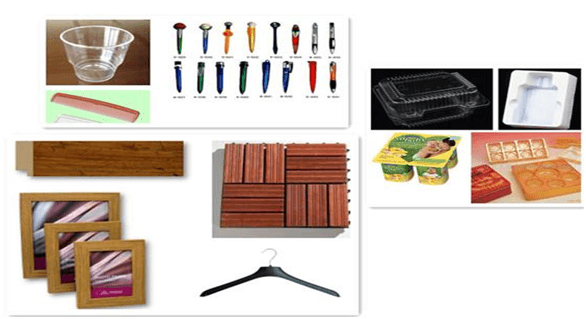

Application in disposable containers:

One of the most common applications of polystyrene is its use in the industry of making disposable and recyclable containers. We now see that these disposable products play a very important role in industry and human daily life.

There are several reasons for using polystyrene in this field, first of all, transparency and then very high resistance of this plastic material. This has led to the use of this material in addition to disposable utensils in the automotive industry, sports equipment, most sanitary ware as well as making toys for children.

The dielectric capacity of polystyrene molecules has caused a great deal of attention and polystyrene is considered one of the important compounds in the electronics industry.

Use in home appliances:

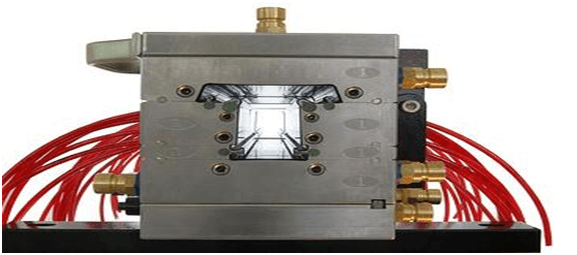

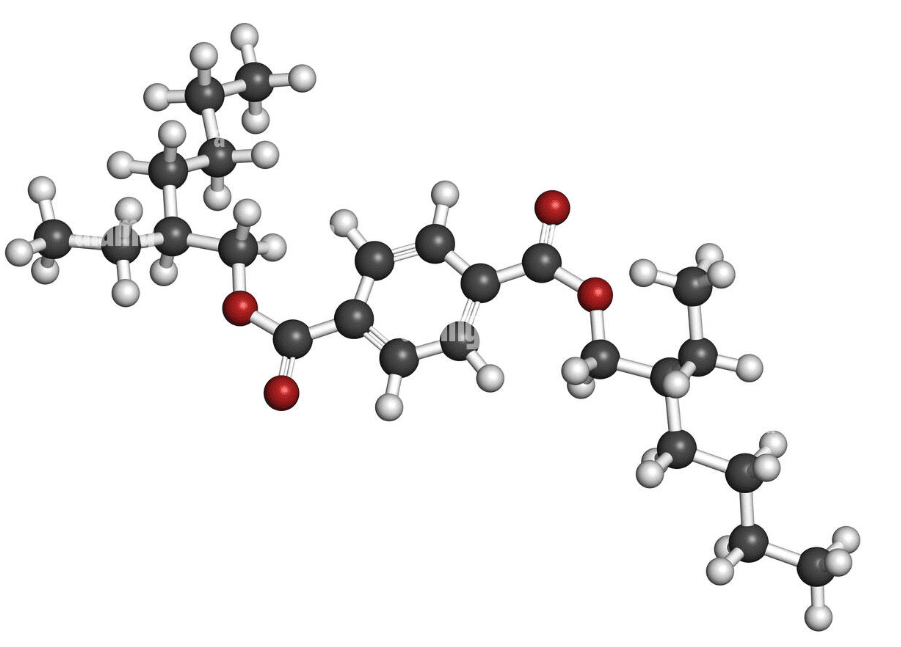

Another application of polystyrene is the use of impact-resistant polystyrene. This model of polystyrene is a modified and more durable example, also known as co-polymer. This product has directly found its place in the production of home appliances.

With the improvement of impact capability in this material, more applications have been defined for it. This type of polystyrene is commonly used in the production of floors, shelves, and trays inside the refrigerator, a variety of home appliances, audio, and video appliances.

Applications of polystyrene

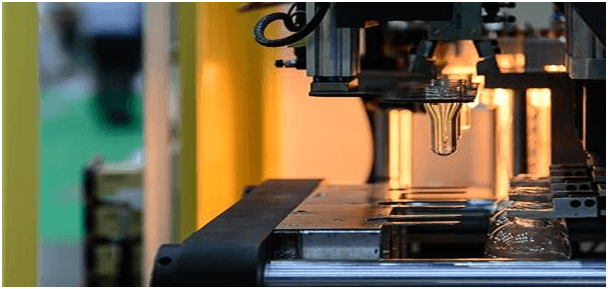

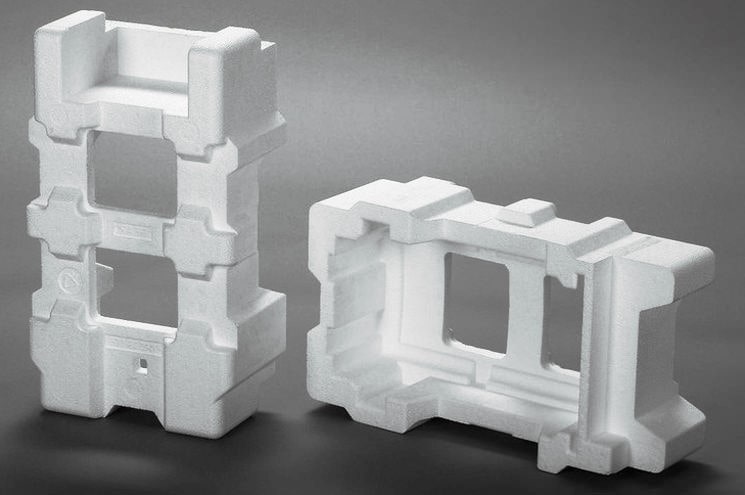

EPS polystyrene:

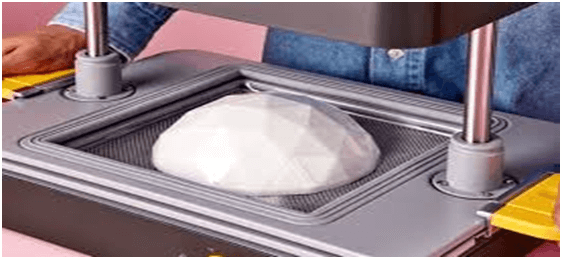

This type of polystyrene, which is supplied in white and is known in our country as Ionolite, is mostly used in the production of sandwich panels. Features of this type of polystyrene include high resistance to compression and high impact resistance, as well as very low thermal conductivity and lightweight. These features have made this polystyrene widely used in various industries such as packaging and insulation.

Applications of expanded polystyrene include its use in the manufacture of blocks, which is known as the best substitute for cement blocks. Another application of this material is its use in industrial refrigerators as thermal-cryogenic and sound insulation.

Medical industry:

Polystyrenes are widely used in the medical industry due to their transparency and easy sterilization. These materials are used in the manufacture of trays for tissue implants, various types of medical devices and equipment, in the manufacture of test kits and Petri dishes, diagnostic components, and laboratory tubes.

Use of polystyrene in food packaging

One of the things that have received a lot of attention when using polystyrene is the use of polystyrene in the food industry. In response, it should be noted that the European Food Safety Authority and other regulatory agencies have reached a common conclusion that there is no problem with food packaging.

Food packaging not only has its disadvantages but also its advantages. These benefits include helping to reduce foodborne illness in hospitals, restaurants, schools, homes, nursing homes, Internet cafes, and more. The use of polystyrene in packaging is very cost-effective and reduces costs.

Use of polystyrene in food packaging

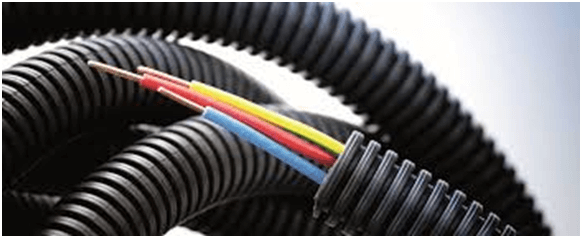

Use of polystyrene in buildings

Undoubtedly, one of the most important applications of polystyrene is its use in buildings. Polystyrenes are commonly used as insulation in the construction industry and have a minimum thickness of about 1 inch. This material is usually used as insulation in ceilings and walls.

Polystyrenes are highly resistant to moisture and water. These materials show high flexibility and adaptability to high temperatures. Other features of this material are high stability against earthquakes and its lightness and easy transportation.